We had a great last day sailing Skyward our 1996 Catalina 34 Mark II. It was a phenomenal day on the water, actually. This would be some of our last few moments on this remarkable and well-maintained boat.

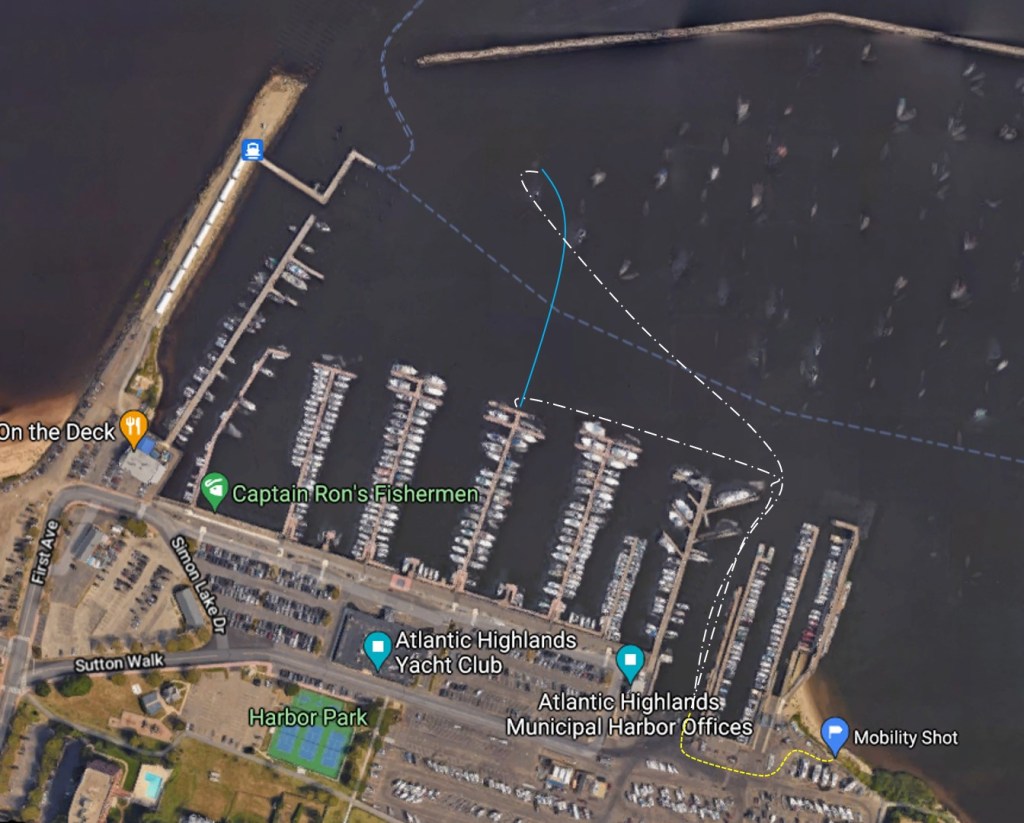

The boat was launched by the Atlantic Highlands Marina crew who took their time. We watched them move the boat through the marina using their tow cradle, then carefully transfer to the boat lift, move the boat gingerly to the loading dock and then gracefully lower the boat into the water. That is quite a feat.

The crew chief signaled to me to get on the boat, and I was suddenly caught in a moment of reflection remembering the exact moment that a marina crew asked me to board the boat the day that we bought it at the exact same step in the sequence of launching the boat.

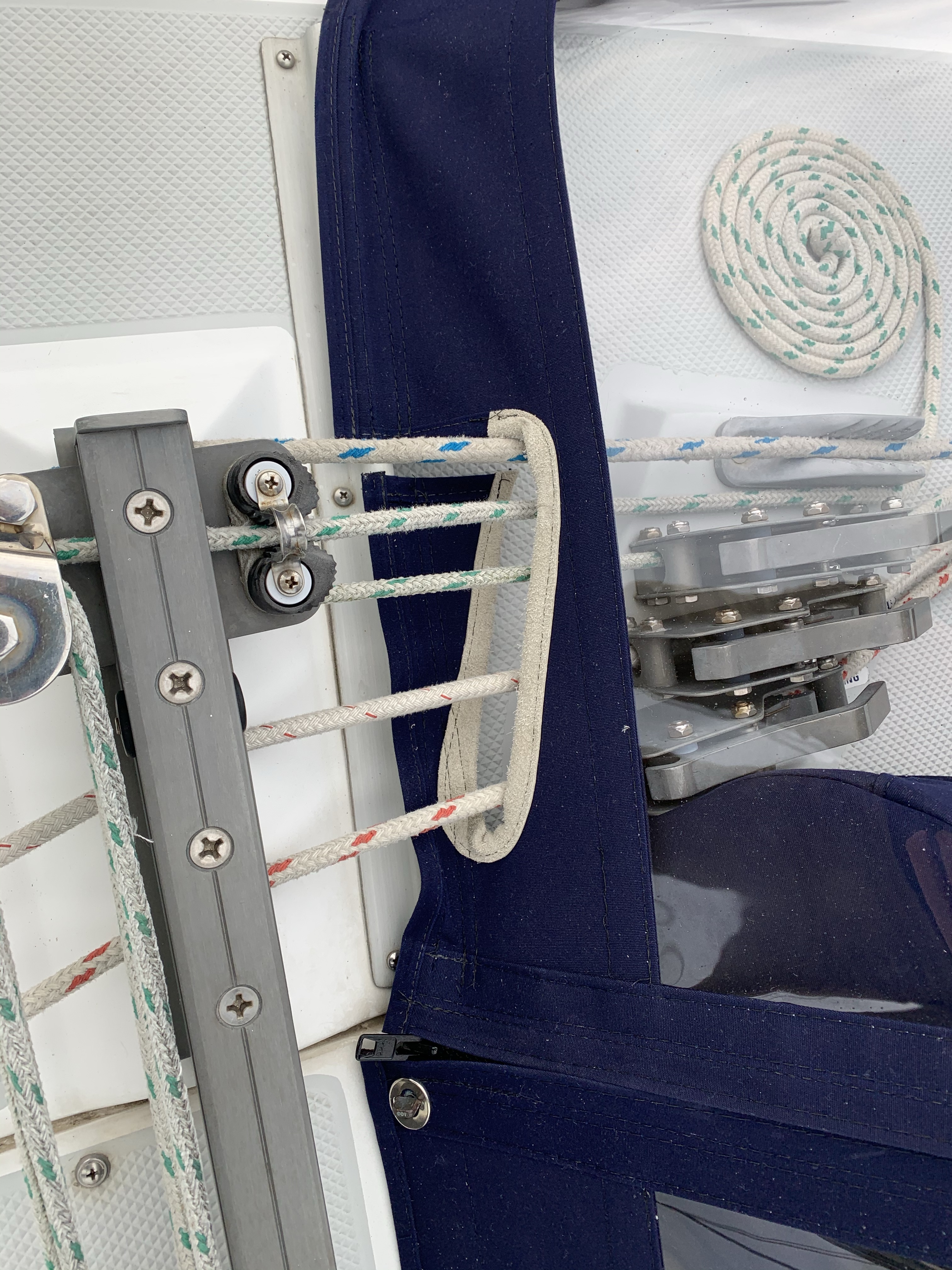

I realized that the battens from the original sail cover were longer than the batten pockets sewed into the new sail cover. But I was just a little lazy and left them for the next owner to cut a few inches down to size.

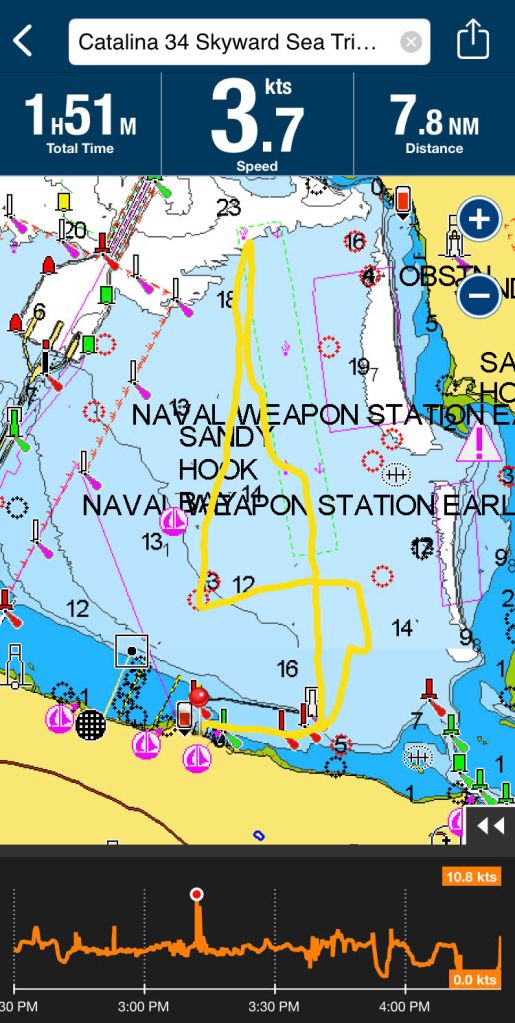

The sea trial was spectacular, superb, sublime. We had about 15 knots of wind, hardly any waves and no boat traffic in the Sandy Hook bay. Most of the time we clocked 5-6 knots of boat speed. You can see that we had a nice long stretch on a beam reach.

The rest of the canvas work was completed over a period of a couple of days with a new dodger, bimini and helm cover. I like the color and the new crisp and clear windows. I’m not yet sold on the traveler and sheet pass-throughs, but the boat isn’t going to be mine soon, so the new owner will have to contend and make up their own mind. But check out that water and how calm it was. We couldn’t have asked or nicer weather for this work.

Something few people would understand is the amount of effort it took to get the boat back onto the mooring, just a few hundred feet away. I needed a 2nd hand to move the boat, so I waited for a friend to bring their dingy. Their dinghy motor failed, again on them. So we milled around for a half hour late in the day trying to figure out the problem and see if we could find another boat. No luck. We only had ONE option to get this done. So we went back over to the dingy rack where our (still ours for a few more days) 9′ AB dingy that doesn’t have a motor on it. Don’t ask me why the new owners didn’t want to buy our 9.9 hp Yamaha. I hate, absolutely hate, to take the dinghy off the rack and move it to the launch and then perform the launch process. It is such a pain and hard on my body to do this work:

- Check the tubes for air pressure, pump up if needed

- Remove the cover and set it aside somewhere to not get dirty

- Unlock (untie) the dingy from the rack

- Install the beach wheels

- Pull the dinghy off the rack

- Tilt the dinghy to drain out massive amounts of rain water

- Put in the drain plug

- Lift the dinghy on one end and hand walk it 500-1,000 ft to the launch using the 2 wheels as the pivot and main structural support

- Roll the dinghy backwards down the launch and into the water

- Take the painter attached to the bow and pull the dinghy to the launch dock

- Tie it up to a cleat and climb in

In my work clothes (*sweating profusely by now), we both sit in the dingy and have to determine how to row it with the winds that have just picked up some steam. Thanks, wind. We row the dingy out into the harbor and across to the Catalina. Tie it up then we move the boat to the mooring without incident. Then we begin the whole process all over again to row the dinghy back to the launch and reverse all of the steps to put it away again.

I will say one thing for sure…with all of the sweat and tears, I’ll miss this dinghy and these wheels are backsavers!

Last October during a hectic day while installing the Winter cover, I accidentally and without thinking removed the reefing line completely from the boom. I knew that I would be haunted by this in the future. This came up during the sea trial as an item, so I felt compelled to complete the work and not leave it for the new owner. To me, it is a safety thing and I wouldn’t want a new owner unfamiliar with the boat to not have the reefing line at least at-the-ready in case they encounter unexpectedly harsh weather. I bought an electricians snake a long one and it was stiffer than I thought it would be. Once I opened up the aft end of the boom, I saw my work was cut out for me, because I had to get the reefing line inside the left-most aluminum extruded pocket at the aft and fore end of the boom. But I had no easy way to run the snake forward or backward and pick up the end of the snake to fit in between the bottom of the sheave and the alumunim frame/pocket. I improvised 10 times and finaly figured it out!

They always say that the two best days of your life are the day you buy your boat and the day you sell your boat. But this wasn’t our happiest “day” to see the boat being sold. We worked hard and devoted a lot of time to fixing it up. We felt very comfortable sailing this boat, and it was in really good shape because it was maintained well.

Stay tuned for our next journey!