When you buy a Class A rated ocean sailboat that is highly engineered, it comes with a long list of equipment and systems that must be constantly maintained. We enjoyed many “arrive and drive” days with our Catalina 34, but this Hallberg-Rassy as with many boats of this era and complexity reminds us that we are operating a ship. As an owner of a vessel like this, you have to be prepared to jump into a wide variety of problems and issues. Here are some examples.

Thanks to what we are calling ‘No Wind August & September’ in New Jersey, we have plenty of time to sort out these projects.

VacuFlush

We got our hands dirty. We really mean it, we started to work on the vacuum leak of our forward toilet. The VacuFlush system works great. When you push the flush pedal, the vacuum system sucks the waste out of the toilet into a small receiving tank and then pumps it into the holding tank. The hose on the right is pumped up to the holding tank. Well yes, when you disconnect that line, shti happens. Literally. We had crap all over us, the v-berth and the forward bilge. That took hours to clean up. The system still isn’t fixed. We haven’t given up, though.

(Is the) Mainsail to Big?

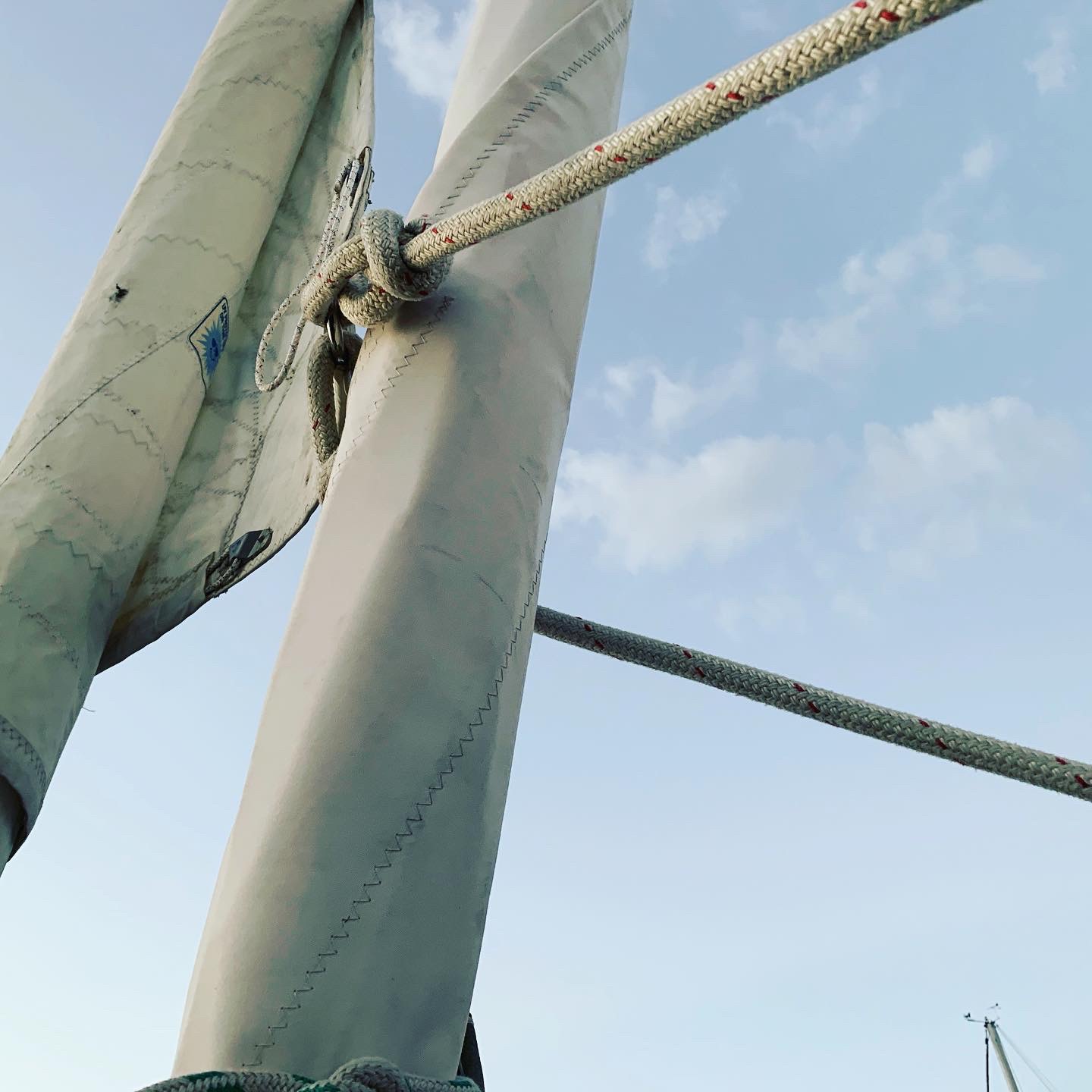

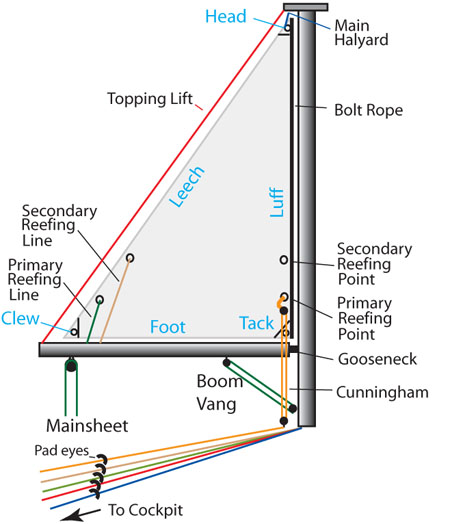

We’ve raised the mainsail dozens of times and every time we do it, it doesn’t seem to extend the luff or the foot of the sail tight. Also, the last 6 inches seem to be putting the system under very high tension. We don’t always feel that we have a fully raised mainsail.

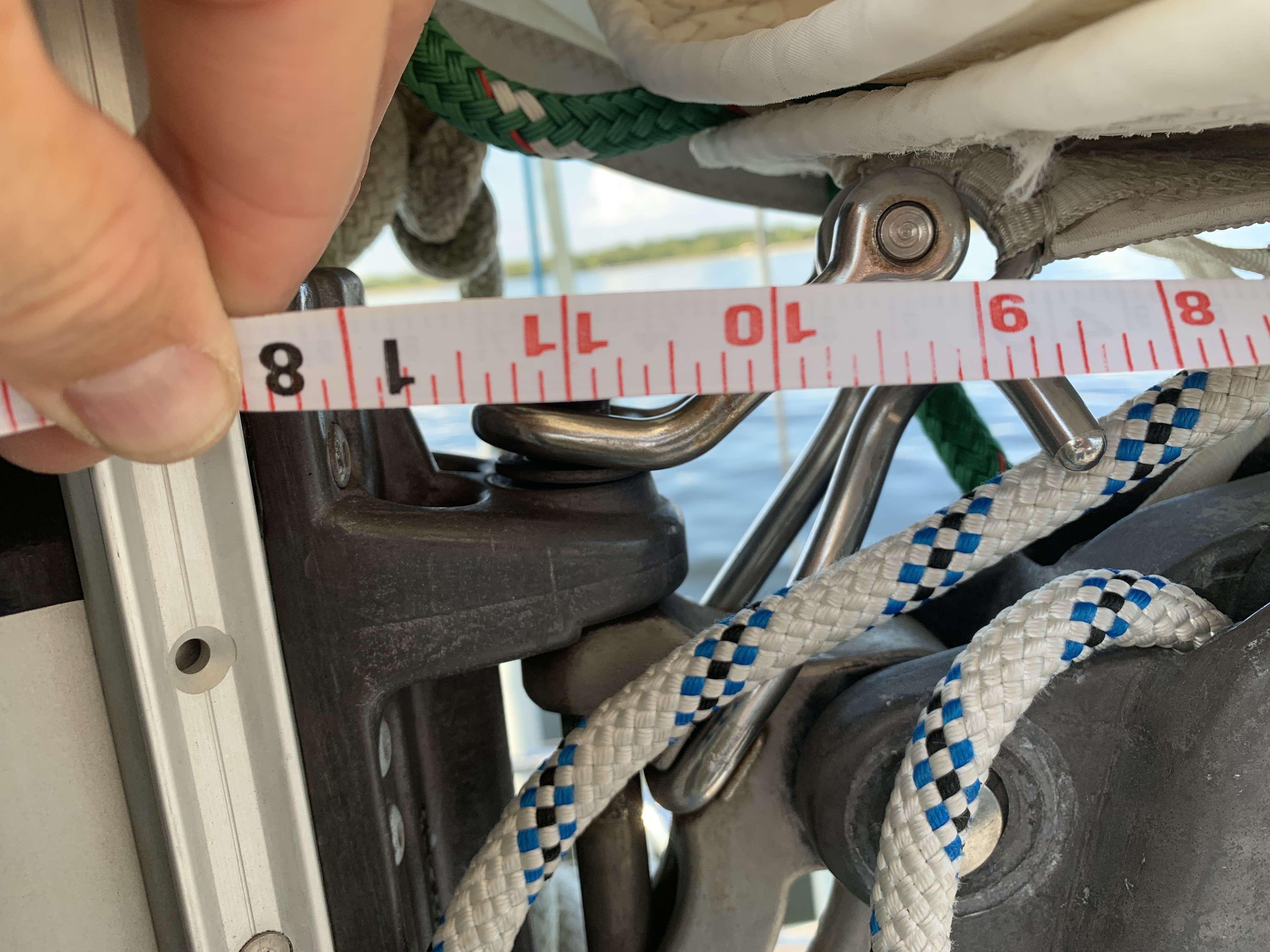

The bowline and main shackle are 5″ long

Is it all the way up?

The luff and foot appear too long

When that happens, the sail looks like it is too big like a child wearing an adult shirt. The sail also doesn’t perform as it is intended which means less speed. We started taking measurements of the luff up the mast and the foot along the boom. Our first thought was that the sail maker (Quantum) may have either missed something during the fabrication process in 2015 and wasn’t caught by the previous owner who installed it in 2017.

What we forgot is that our backstay adjuster was tensioned to 1000 PSIG. With that force pulling the the aft end of the mast, the mast rake (or bend) is significant enough that our mainsail would not fully raise. Once we loosened the backstay adjuster, the mainsail fully extended with a taught luff and foot. Problem solved…we hope!

Propane Tanks

Simple, right? Just like your BBQ tanks? Nope. Empty marine propane tanks are not simply exchanged for another filled tank. They must be filled by a licensed propane supplier. Tanks are stamped with a date. If the date exceeds 12 years, fillers in the USA can deny your request to fill the tank with propane due to liability. We have two custom 20-lb tanks that perfectly fit into our propane locker. Our tanks are from 2005, and the original distributor in New Zealand is out of business.

Not even a 1/2″ inch bigger in diameter would work

More Sail Issues

Our genoa sheets keep getting stuck on the furled up jib which is just in front of it by about 6 inches. When we pull on the working sheet, it builds up tension, because the jib it in the way and is working against us trying to unfurl the genoa. We figured that our bowline knot on this 3/4″ line is too big and bulky. Next year, we will used a different knot to pull on the clew of this sail

Hard Landing?

Our boat was hitting the ground all summer while on the mooring – twice a day. With the keel buried into 1 foot of muck on the bottom of the harbor, the boat would not move with the changing wind patterns. When the tide ebbs and we reach low tide, the water level empties out of the harbor and our boat sits on the ground. Whenever this happens, we have about 1-2 hours where our boat is fixed in position and cannot move even if we turn on the engine. We had a number of very close calls with nearby boats that we freely swinging on their mooring during low tide. Fortunately, we were able to move to another mooring with another two feet of depth under our keel.

Leaks

We discovered a leak in our Hot Water piping system. Rachel saw water dripping down from above in the cockpit when we were working on the engine one day. We ran upstairs, tore open the lazarette, and sure enough, the hot water distribution piping was leaking and raining down on top of the generator below. After the purchase of necessary parts, the system is back to being leak free.

Way Up There

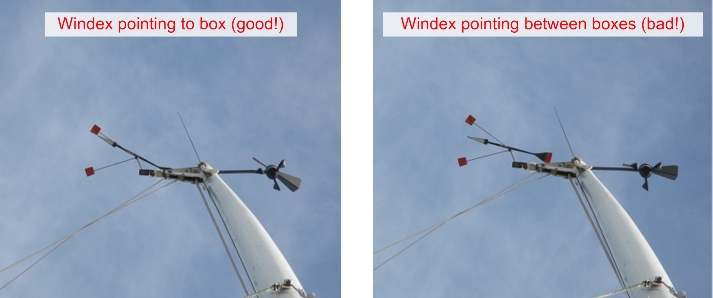

65 feet in the air, the Windex telltales at the top of the mast were loose. This happened on our first trip out of Herrington Harbor North a few months ago. Fortunately, the previous owners installed fixed steps on the mast for me to climb up safetly. I do need to wear leather gloves, because the edges of the steps are sharp.

Last photo courtesy of http://northern-light-sf.com/

Back to the Genoa

Our NorthSails Genoa from 2018 is too short creating halyard wrap. This was not known by the previous owner, and we did not see this upon our survey, sea trial or after over 500 nm of sailing. But we did feel the incredible tension required to unfurl and furl the genoa. We had to use an expensive and powerful 24v Milwaukee drill to unfurl and furl the genoa. We thought the problem was that the furler and the upper spindle were not cleaned free of salt residue and greased. So we pumped grease into every bearing slot and hole that we could. That helped out a lot, but that didn’t solve the problem entirely.

The root cause was that the luff of the sail was about 5-6″ too short, and this caused the halyard to wrap around the forestay when the tack of the sail was secured to the furler. The genoa being too short is not a problem -the sail works just fine. But the halyard wrap is a problem and can be a dangerous problem that could jeopardize the integrity of our standing rigging. We fixed this temporarily by installed a homemade 5-6″ strop .

We could grease most of the furler in place, but we couldn’t access the inner race of the furler while it was installed, otherwise we would lose the ball bearings in the water.

Let There be Light

Just walking by the galley one day, I saw the light above galley broke such that it was just hanging down. I was trying to leave for the day to go back home, but I knew I couldn’t just leave it like this. Out came the Gorilla Glue. All fixed!

In addition there are dozens of other projects that we’ve worked on this summer. Some were relatively easy and others very challenging:

- Replaced engine raw water impeller – as a precauion, we replaced this. Lucky we did, because we found a couple of significant tears on the backside of the impeller that a simple visual inspection would not have caught.

- Jib furler drum broke – I pulled the furling line too hard one day and snap! The plastic furler drum cracked. It took a lot of force to make this happen, and I should have stopped cranking on the winch. Our Furlex 300 drum has two halves, and so I could’ve re-used the good half instead of purchasing a new one.

- BBQ regulator is missing – Thanks to the previous owner, we couldn’t hook up a propane bottle to our BBQ. There was no regulator, and this BBQ is no longer made. We found a regulator online that did the trick after some tweaks.

- Fixed the broken traveler car – Our traveler is no longer made by Lewmar. We had Ray make up a custom piece for us.

- Replaced multiple cabinet door latches – Also, latches are no longer made and hard to find

- Replaced compass light bulbs – A simple project but hard to find 24v light bulbs that fit our compass that is no longer manufactured.

- Riveted the hold downs on the salon hatch – Corrosion is the killer on these boats. Luckily, we found the right size rivets.

- Generator, generator, generator – It still won’t start, but we know what the problem is now

- Replace both alternators and the high output regulator – After a small fire, we have replaced both alternators. No issues with battery charging now.

Hopefully you get the theme by now. Boat manufacturers design the boat and build the hull from scratch. They are master integrators. They buy components from other manufacturers and attach them to the boat in the configuration that they desire to provide whatever unique capability they want to provide to their customers. A boat like this that is more than 20 years old is hard to find spare or replacement parts for, because those manufacturers either 1) have gone out of business or 2) have continued to develop and improve their product lines.

That may not be a problem in times where massive inventories of parts were available on shelves, manufacturing companies were able to remain fully operational with workers and demand, and where supply chains were agile. Those were the good old days. Enter the COVID pandemic and incentives to work from home. Boat sales went through the roof, spare and replacement parts inventories dried up, and parts companies are unable to meet the pent up demand.

If we had to do it all over again, we might not have purchased a boat like Skyward that is this old at this time. We might have looked for a boat that was 10-15 years old where the parts weren’t as corroded or in need of repair. (I have to be careful, she might be listening to me and she will make me pay for these words).

We’re working hard to make Skyward fully seaworthy once again!