NON-SYSTEMS

In the water at a dock (Atlantic Highlands Marina and Norwalk East Cove Marina):

- Removed flaked and folded mainsail including the reefing lines

- Removed flaked and folded jib

- Removed flaked and folded genoa

- Removed dinghy motor

- Removed sail bag (Mack Sails)

- Removed the 2x large propane tanks

Out of the water (Norwalk East Cove Marina):

- Pull back all lazy jacks to the mast

- Removed the dive air compressor

- Removed the 2x dive tanks

- Dropped the spinnaker pole onto the deck

- Dropped the MOB pole onto the deck

SYSTEMS

Here’s what we accomplished out of water on SBS-1 stands:

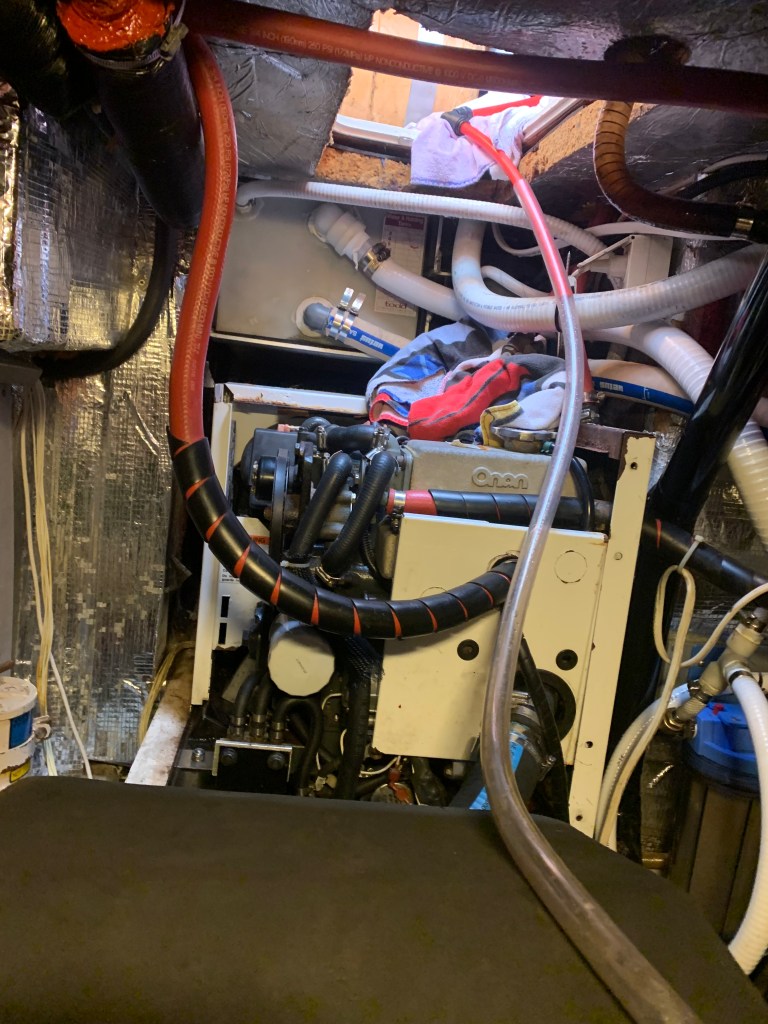

023 – Generator (2 gallons)

- Disconnected the tubing from the discharge of the seawater strainer hanging on the aft wall of the engine room towards the starboard side. This line directly flows to the inlet on the front of the generator. Had to clean up a little spilled seawater.

- Filled a small bucket with a gallon of antifreeze. Opened another gallon and had it ready. Put the bucket just behind the engine transmission on the floor of the engine room.

- Put the generator seawater supply line that was disconnected into the bucket and submerged it.

- Reached up and started the generator.

- When the bucket began to empty, poured in the 2nd gallon.

- As the bucket began to empty a 2nd time, tipped the bucket to get as much out.

- Stopped the generator.

- Re-connected the supply line to the discharge of the seawater strainer.

- Seacock is closed.

009 – Engine (5-6 gallons)

- Closed the seacock

- Opened and cleaned the large black plastic strainer hanging on the aft wall of the engine room on the port side above the steering system. Left it open with the top off and the screen out

- Filled the strainer to the brim with antifreeze

- Opened and staged 5-6 gallons of antifreeze with tops off and lined up at the engine room doors

- Started the engine

- Ran down and successively poured 5-6 gallons of antifreeze into the opened strainer while the engine was running. This happened very fast, about as fast as you could move your arms to pour and not spill or splash.

- Killed the engine just before the strainer was 1/2 empty using the kill switch on the engine. Turned off the engine key at the helm.

- Verified antifreeze exited the boat through the proper port. 5 gallons might have been enough

- Re-installed the clean strainer and covered it

- Left the seacock closed for the winter with standing antifreeze in the line

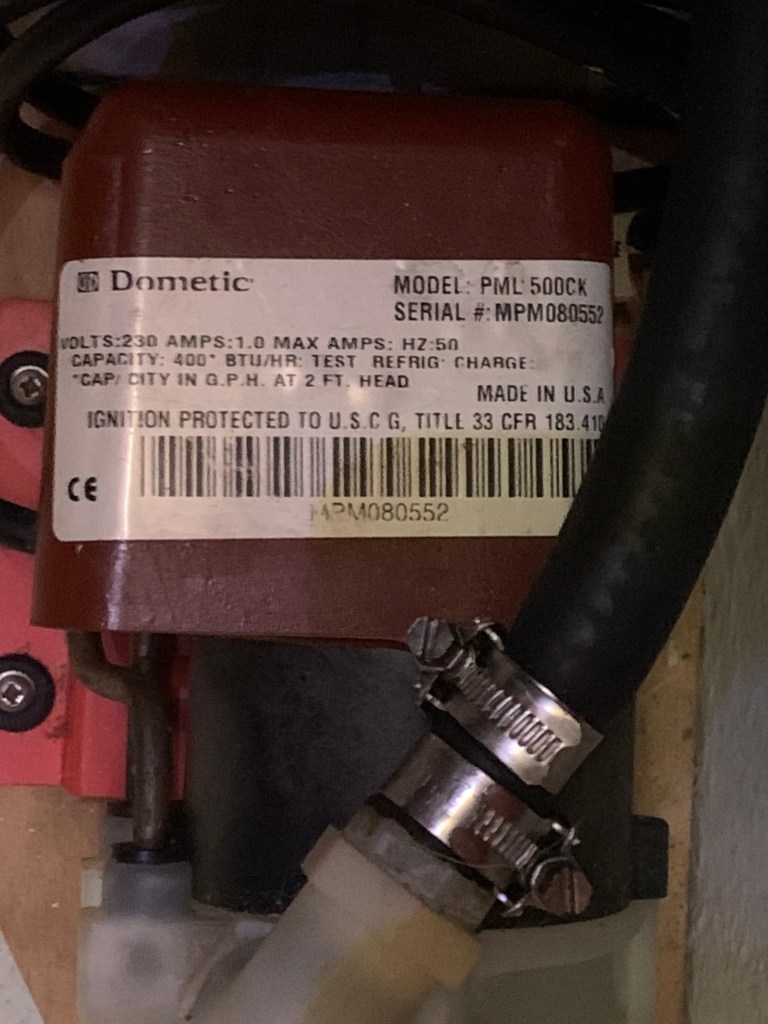

002013 Air Conditioner (1 gallon)

- Disconnected the inboard seawater line on the discharge of the strainer in the forward passageway bilge.

- The water pump lost prime and would not pick up anti-freeze sitting in a bucket. Here are the steps we took to prime the pump:

- Using a small funnel and filled the tubing which leads to the pump suction side from the point where it was removed from the stainer in the passageway. That was not successful

- Removed the seawater discharge line from the discharge thruhull valve on the starboard side behind the settee. Using a small funnel and filled the tubing which leads to the condenser outlet which leads to the pump discharge. That was not successful.

- Tried to remove the pump discharge tubing at the point where it connects to the condenser inlet. Had to tank off the rectangular air conditioner grill below the settee to access this. The tubing seems to be fused onto the condenser inlet and no amount of force could be applied to remove the line without damaging or destroying the tubing. That was not successful.

- Removed the pump discharge line at the point where it comes off of the pump. Tried to fill the line forwards towards the condenser inlet. Due to elevation, this was only able to put < 1 cup of anti-freeze into the tubing. Tried to quickly re-attach the tubing to the pump discharge. That was not successful.

- Pulled out the long polygon tubing with integral drill pump. Connected the end to the pump suction tubing that was still disconnected in the passageway. Using a funnel to fill the tubing and also a battery powered drill to force coolant into the head of the pump. This provided ample Net Positive Suction Required (NPSHR) to prime the pump. This was successful.

- We started the air conditioner, and the pump was flowing, so we continued to pour around 1 +/- gallon through the system using the funnel and drill pump to flush it and leave anti-freeze in the system.

- Turned off the air conditioner system.

- Closed the thruhull valve on the seawater discharge on the starboard side behind the settee

- Re-connected the pump suction tubing to the discharge of the seawater strainer.

- Closed the seawater seacock in the passageway bilge.

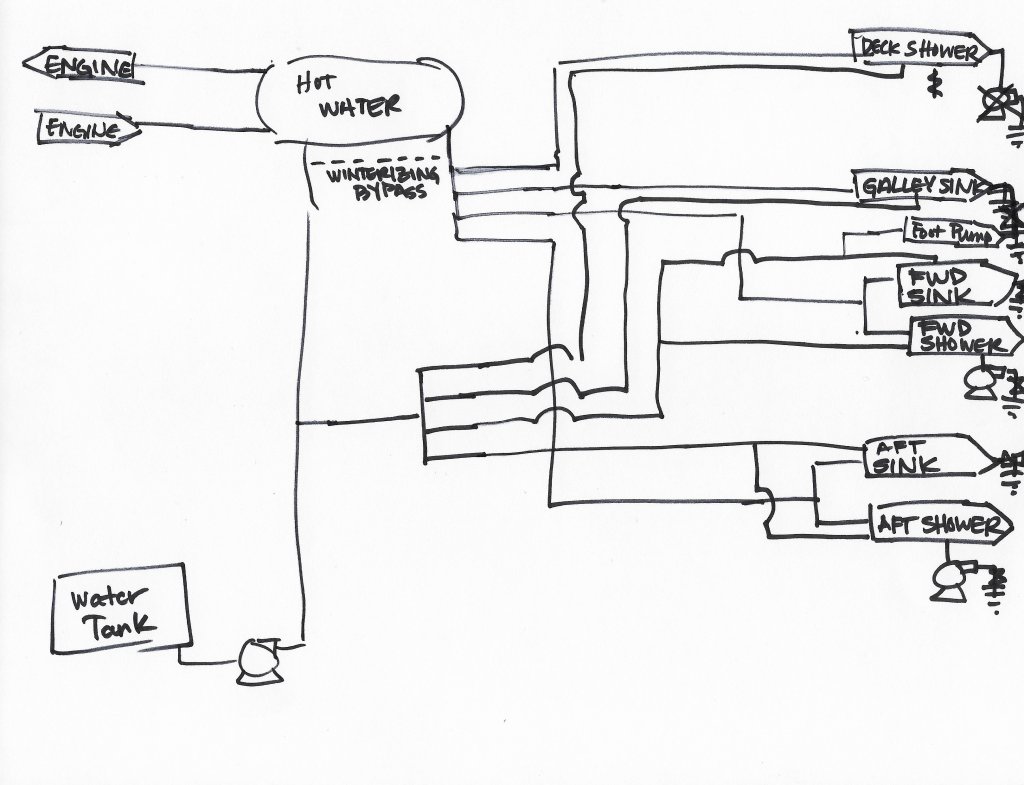

014017 Hotwater

- Removed all items from the cockpit lazarette including the wood paneling that conceals the hot water tubing and tank.

- Removed the seawater strainer lid at the aft and portside of the engine room that feeds the watermaker, the refridgerator and a few other systems. Ensured that the seacock valve was open.

- Opened the engine room door above the generator from the lazarette.

- Disconnected the system tubing.

- Connected a long polygon tubing to the discharge of the hot water tank system down through the hatch doors and directed it into the seawater inlet hole of the open strainer. The flowpath was from the hot water system down to the strainer and out the seacock.

- The entire system was drained, and it took about 15 +/- minutes perhaps longer.

- Removed the polygon tubing and connected the hotwater bypass completely.

- After the freshwater system was flushed with anti-freeze, reconnected all of the original lines and pressurized the system to ensure no leaks.

014013 Freezer (1 gallon)

- While the hot water system was draining…

- Ensured that the seawater discharge thruhull valve was open on the port side behind the setteee.

- Similar to the air conditioner unit, we had to prime the seawater pump.

- Removed the seawater pump suction tubing from the discharge of the strainer located on the outboard side of the passageway bilge.

- Inserted the long polygon tubing with integral drill pump.

- Using a funnel and filled the tubing with anti-freeze and used the drill pump to increase NPSHA and prime the pump.

- Turned on the freezer (“COOL BOX”) and let the pump run.

After 1 +/- gallons stopped the process and verified anti-freeze was discharging at the thruhull. - Re-connected the tubing to the strainer.

- Closed the seawater discharge valve at the thruhull behind the port settee.

014012 Refridgerator (1 gallon)

- Filled the seawater strainer with anti-freeze.

- Turned on the refridgerator and let the pump and compressor run.

- Re-filled the seawater strainer until about 1 gallons went through in total.

021 Fore and Aft Heads (2 gallons)

- Poured 1 gallon in each head and flushed it into their holding tanks

007 Seawater to Sink and Deck Wash (<1 gallon)

- Filled the seawater strainer with anti-freeze.

- Turned on the seawater pump to pressurize the system.

- Connected a hose to the Deck Wash (anchor basin) and turned on the spigot.

- Directed the hose overboard and waited to see anti-freeze coming out.

- Turned off the spigot for the Deck Wash.

- Opened the seawater faucet at the galley sink and shut the faucet when anti-freeze was observed coming out.

- Re-filled the seawater strainer until we saw pink at each use point.

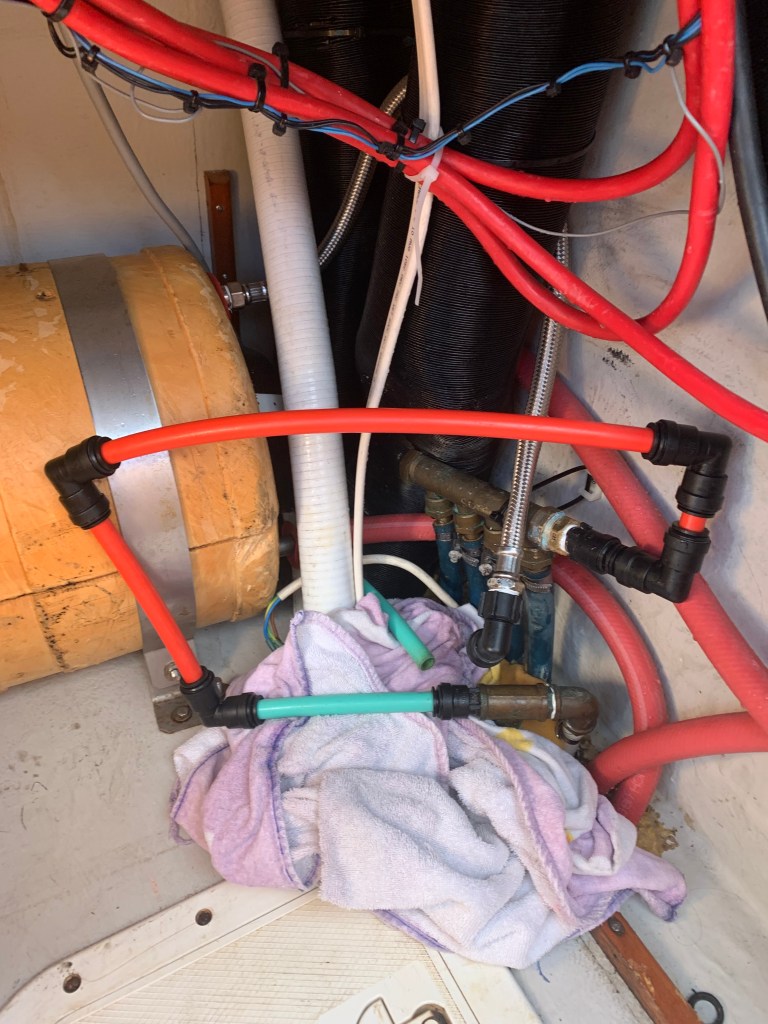

022 Freshwater to All Sinks, Showers and Aft Shower (5 gallons)

- Poured about 5 gallons total into the freshwater tanks from the deck.

- Turned on the freshwater pump to pressurize the system.

- Make sure that the hotwater bypass set up is not leaking.

- Opened all cold and hot water faucets at all sinks (fore head, aft head, galley) and showers (fore, aft). For the fore and aft showers, also turned on the drain pumps.

- Connected the HR spray hose to the aft deck shower and tried to flush it with anti-freeze. Fluid flowed through it, but it is definitelyu not the right size.

- Closed all drain seacocks.

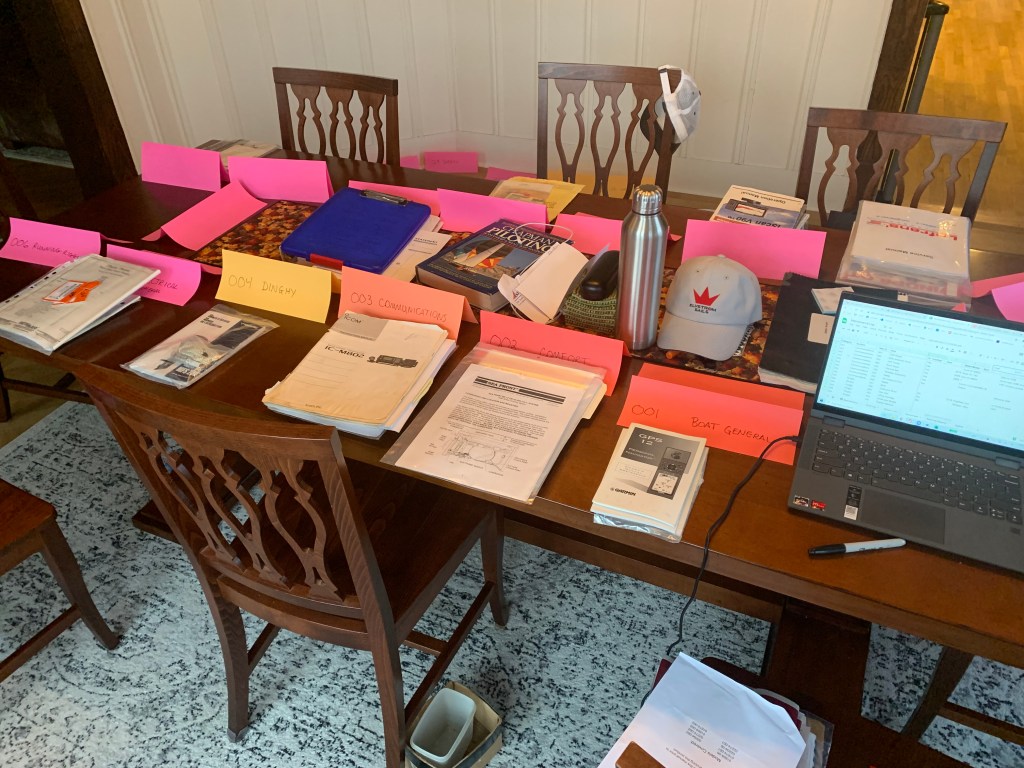

We also organized all documents for the boat into categories. This was a big job!

The marina installed shrinkwrap, which was our first time. This is pretty cool!

Wow, amazing job, JEFF!! You were very thorough in Winterizing “Skyward”!! So very proud of you Son!! So glad you shrink wrapped her for the Winter! Great job!!

LikeLike