The project list as always is ambitious. Projects take on a life of their own, having to contact vendors, service providers etc. Just removing old or broken parts is a project in and of itself.

Onan 4.5 kw Generator

Now that we have gotten our generator running with an investment of nearly $7,000 (!!!), we want to improve it’s appearance. Now I know what you are thinking, that is a lot of money. It is. In hindsight, it may not be the best use of money. However, the cost of a new generator and replacing it in the engine compartment would probably greatly exceed $10,000, and to be honest, we just don’t have the time or energy for that significant of a project. You have to remove the hatch (which we need to do anyway), then you have to clear out the engine, and as the project is going, it would turn into death by a thousand cuts, because there are so many things we would be compelled to fix or replace while the old generator had been removed. It would be a financial and time trap. We just wanted this unit running. It only has 900 hours on it. Let’s get it going and use it for a few years (hopefully fingers and toes crossed).

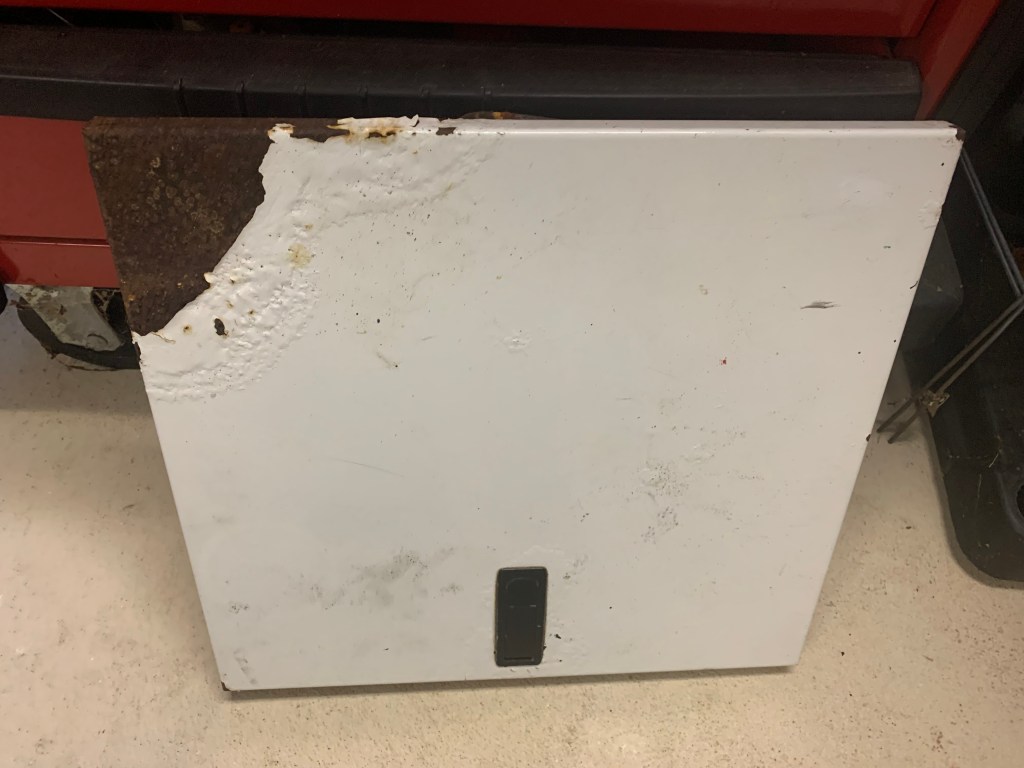

Almost all of the sound proofing panels are corroded from the water leak we discovered in the hot water system in the cockpit lazarette. We have them off the boat and trying to determine whether it is worth it to strip them down, media blast them, have them powder coated and re-assemble them. The insulation is completely destroyed, all sound and “waterproof” seals are worthless, and the metal is highly corroded. Most of the corrosion is surface, but there will be quite a lot of pitting.

I’ve also touched base with Cummins to see if they have some of these panels available in inventory somewhere. I don’t know yet which direction I’d like to go. I could probably have the panels powder coated for $150 — that might be worthwhile. Before I can have the panels powder coated, I would have to completely disassemble them. And that won’t be so much fun.

Bauer Jr II Dive Air Compressor

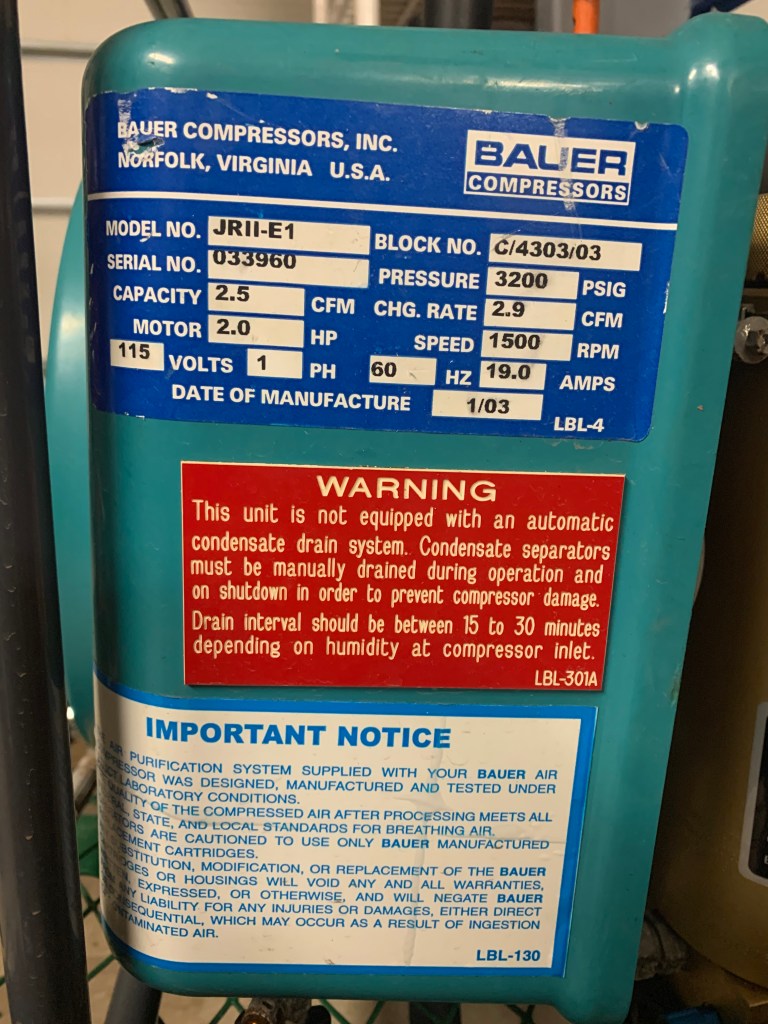

We are really fortunate to have inherited this equipment. Previous owners bought this unit and then had it entombed inside of a weather-protecting teak box fixed on our aft deck. That box (and it’s companion) are at the top of Rachel’s regrets of the boat. She wishes that these knee knocker boxes didn’t exist. I sometimes agree, but I believe some day these beauties will pay off.

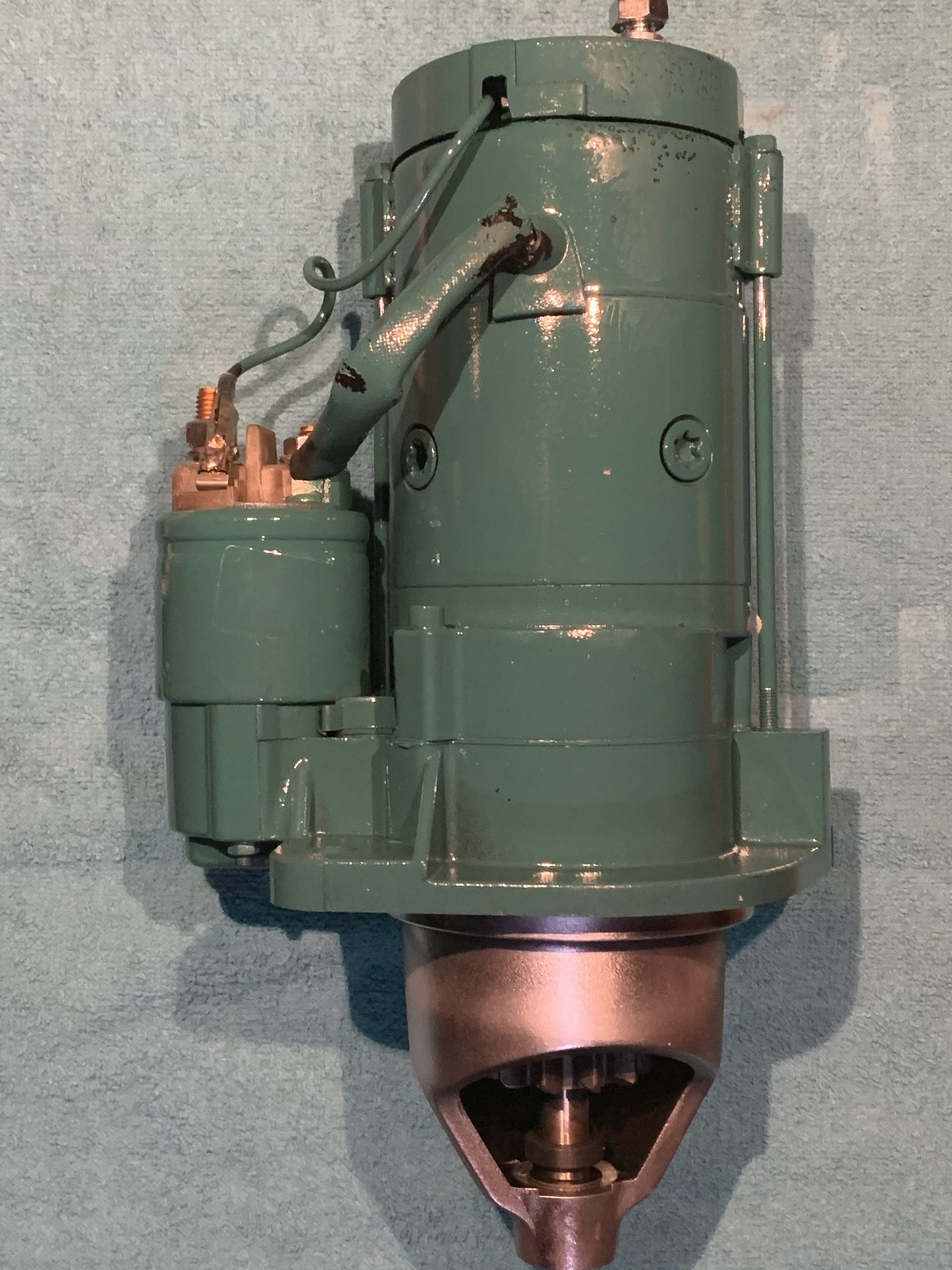

New, these particular units sell for more than $3,000. Our unit is in pretty good shape, with a Honda 5.5 GX160 engine and most of the compressor looks to be solid. The engine was having trouble running, so I cleaned out the carburetor with my brother-in-law, Tim, who is an airline pilot. We had fun doing that on Thanksgiving. I eventually just replaced it for $40 as well as replaced the spark plug. After getting it running somewhat consistently, I decided it was time to completely tear down the unit, because the frame had some decent rust on it. In this process I came to learn that the overall unit was originally an electrically-powered compressor. Some time in the life of this dive air compressor, the electric motor was replaced with the Honda gasoline engine. Good to know! After calling up the Bauer facility in Norfolk, I learned that his compressor was purchased in Southern California. They directed me to a local shop in New Jersey, and within days, I have a complete set of parts coming to me for a modest re-build.

Something we learned after-the-fact is that this unit was originally purchased as an electrically-driven compressor. This should have been wired up to the boat electrical system for power and then an electric motor on the frame would have turned the compressor via the belt. But someone converted this to a gasoline-driven compressor with the swap for the Honda engine.

Lewmar/Whitlock/Mamba Steering

Our steering system is a Rotating Torque Tube & Bevelhead design. I believe it is a Lewmar steering system which was originally Whitlock Mamba. Lewmar must have acquired Whitlock in 2001. Regardless, the steering system is built like a tank. Imagine a 1″ solid tube coming down from the helm and cockpit into the engine compartment, turning 90 degrees towards the aft with beefy bevelhead, and then running to the rudder with more 1″ solid tube, u-joints and a gear box. It is a marvel of engineering.

Unfortunately, previous owners maybe spilled some seawater in the engine compartment accidentally and did not clean up the mess. That seawater corroded a lot of metal in this steering system. So, I ripped it all out and will replace with refurbished metal and new parts.

Starting with removal of the Mamba autopilot. The first thing you have to do with a project like this is take a lot of pictures and label everything especially wires.

Then I tore apart the input and output u-joints and the bevelhead off of it’s base. After disconnecting the output shaft to its aft components, I wiggled the entire bevelhead and apparatus out of its rusted-in position. The mounting plate on the aft of the engine compartment is covered in surface corrosion. That beauty is going to need significant cleanup.

This is a very satisfying job, because I know how important reliable steering is on an ocean-going sailboat. Upon further inspection, we could have had a catastrophic steering failure, because one of the u-joints was 50% functional and had very thin pins in the joints, which means that it was frozen solid and could have broken at any moment. The bevel head output shaft and bearing system appears to be intact and smooth. The input shaft and bearing system seems to be grinding just a bit when I turn them by hand.

I also enjoy tearing things down and trying to put them back together, because it in essence how I learn the best. Needless to say, I have learned a lot about this part of the steering system.

So the next steps in this little project are to media blast and powder coat some of the metal parts, touch up the paint the original autopilot, purchase a new bevelhead and u-joints, then re-install and align everything. I will definitely need to purchase a spare autopilot ($3,500) for when we decide to cross the ocean.