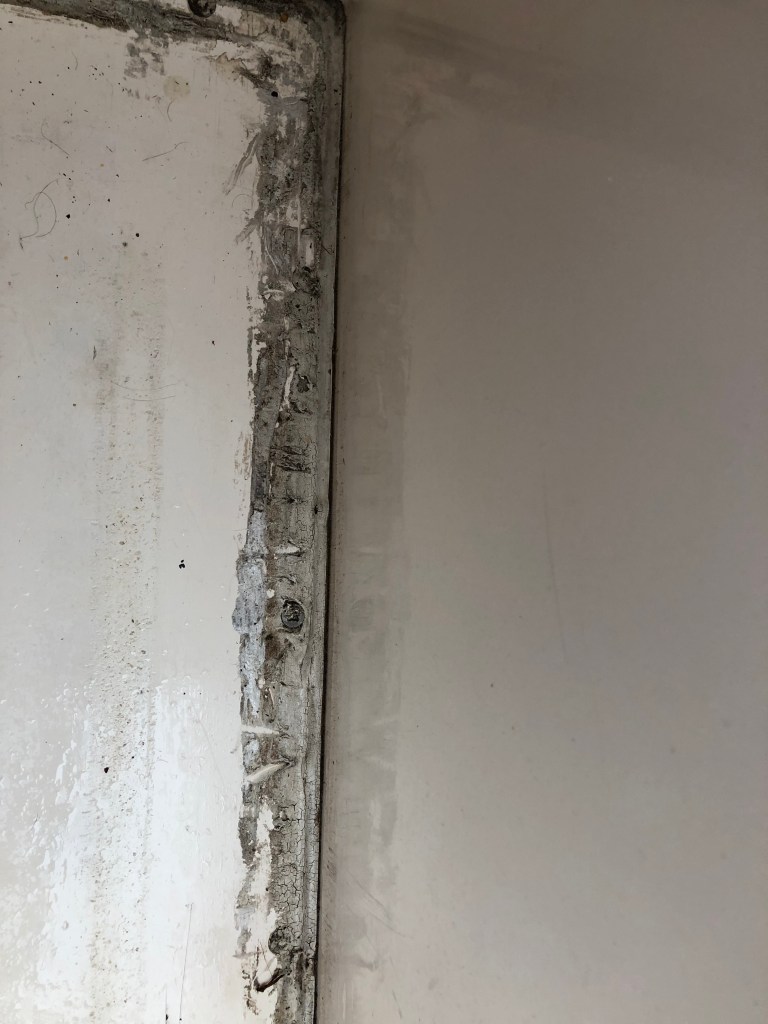

The goal is ambitious to freshen up the engine compartment before we launch. That includes replacing all thru-hulls and strainer thru-hulls, replacing and tidying up hoses, replacing the pressure tank, touching up the engine paint and then re-coating the bottom floor. What started all of this dreaming was not only the disorganization of all hoses and components in the engine room, but also significant corrosion found on certain mechanical bits during the survey and through the past 5 months of sailing.

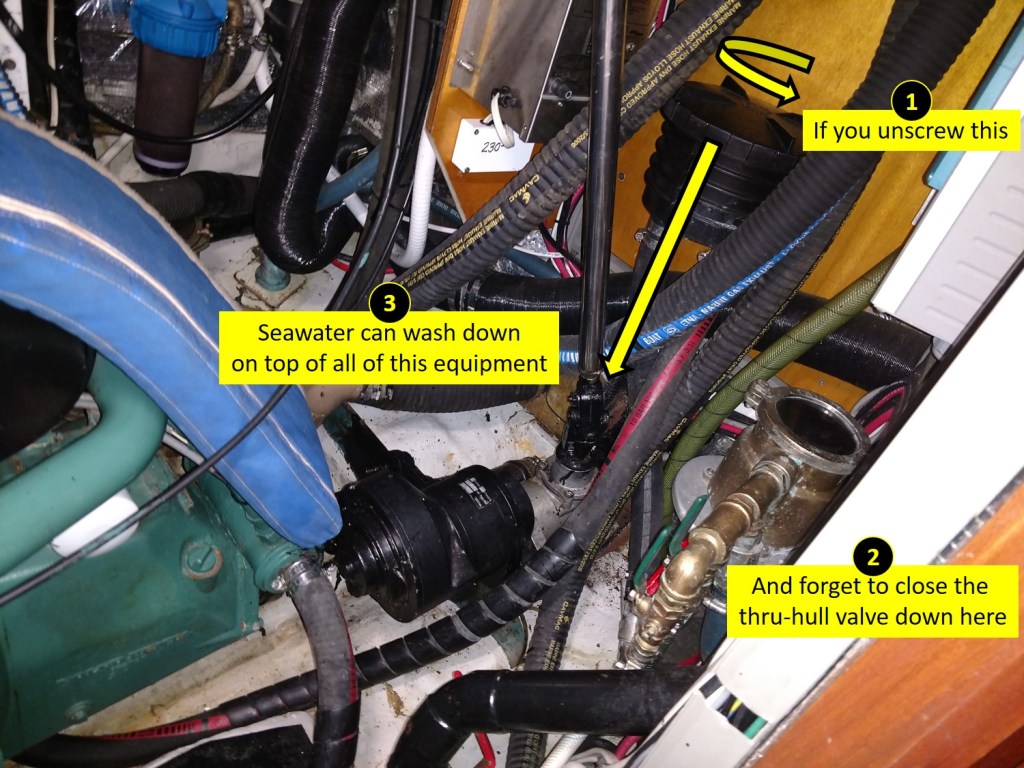

The root cause of the corrosion was a combination of a leaking cockpit floor hatch that opens to the engine compartment -AND- a leaking hot water distribution manifold above the generator.

Just checking the engine raw water strainer also is a great way to splash sea water onto this equipment as well unless you are very careful. I have seen pictures of other HR46’s that have similar corrosion, and I think they have the same issues.

Outside of all of this rust and water entrustion, who can live with such a messy engine room? Those of you that know me know that we need organization!

Skyward is still sitting on the hard in Norwalk, CT covered with shrinkwrap. You would think it would be cozy tucked under a thin layer of plastic. But I can assure you that is not the case. The engine compartment is the coldest part of the boat as all of the cool Winter air sinks to that point in the boat. Our Webasto diesel heaters seem to be coked up, and so we regretably will not run them at this time. To get some heat going, we picked up a 1500W electric heater which if aimed properly, will bring the temperature up in this darkened part of the boat.

I am grateful to the previous owners who were brave and used this boat and proved it around many of the world’s seas. These previous owners seem to have mostly single-handed the boat, so hats off to them.

But if I am honest, the engine compartment of our HR46 is my least favorite place on the boat. That’s why I’m spending so much time talking about it. I’m a neat freak which comes with the territory of being a Lean Six Sigma Black Belt. Here’s why: 1) It seems that previous owners for almost the entire 24 year history of the boat did none ofd their own mechanical work. For the most part, these owners never their hands dirty and dealt with the poor maintainability of bad installations. They elected to pay contractors to install or fix the majority of the equipment. This resulted in disorganization of lines and routings and poorly thought through installations. 2) There is simply a lot jammed into that small space — heaters, generator, inverters, 4 pumps, multiple filters, 8 thru-hulls, etc and 3) It is very dark with poor lighting.

So for me me brightening up the place and bringing some order seems logical and a priority. If nothing else, we will have all renewed fittings and it will make me feel more at ease working in there.

What I’m about to do is put my fingerprint on this boat and will be irreversible. Thru-hulls will come out, lines will get re-run, equipment will have the corrosion removed, and things will be painted. From other posts, you know that I had already removed the steering system in the engine compartment and I had already removed the drive train. Now it it time to cut out the thru-hulls.

So you might say “is this guy just a glutton for punishment? why cut out perfectly good thru-hulls”. Upon inspection, many of these are original thru-hulls with the original wood backing installed. I was not willing to put the boat back togther for another season of sailing when I found a loose thru-hull.

So, I immediately set my sights on the of removal of all of the original thru-hulls in the engine compartment. Once I had all of the steering and drive train components out, access to these thru-hulls was much more convenient.

If you are familiar with these strainer thru-hull assemblies, they are just that — fully one-piece bronze assemblies. Under each hull strainer was nasty growth that is otherwise unable to be cleared. I started to cut sealant around the hull-side perimeter of these with my rotary Dremel. I began going through cutting discs quickly.

It didn’t take long to realize that it would be most efficient to simply cut off the post on the inside of the boat. So I took my 4″ grinder and did what needed to be done.

Using a cut-off wheel, the thru-hull was out in less than a minute. I cut near the base and then sliced into the holding nut. The nut came off in two pieces, and then I could pound on the stub end with a hammer. Some of these integrated assemblies have a screw threaded into the hull on the water side, and so you have to be careful to remove that screw before pounding the assembly out of the boat. The grinder approach did make a mess with bronze particles coating almost every surface.

All three portside strainer thru-hull assemblies on have been removed. One thing to observe is that I need ensure marinas lift Skyward about 12-18″ forward of the position that was used this time around, because the straps go right over top of these strainer fittings which causes cracking/damage.

We’ve decided to install a strainer cover from Groco which can be removed for cleaning each season. We picked up this concept from Ray and also Glen from Cloudy Bay. Makes total sense to me.

Now we are really committed with the 3 of the 8 thru-hulls out of the boat. It feels so good to get this part of the project going.

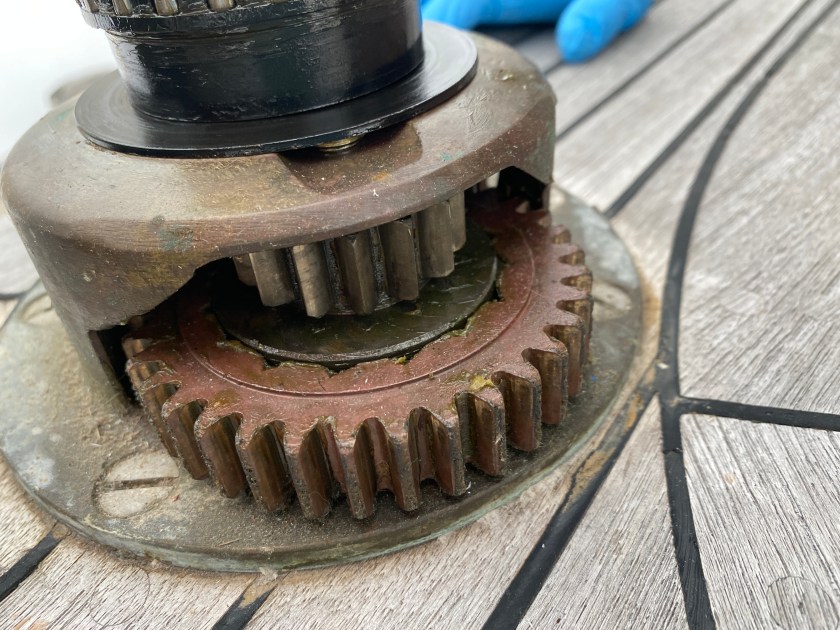

To get some warmth, we moved to the cockpit and decided to work on our 44ST winches. This turned out to be a fairly standard disassembly, cleaning and re-building of the winches. Although since we’ve never done it, we knew this would prove to be an opportunity to learn.

We had a Lewmar Winch rebuild kit on-hand. When I assembled the winch, I used a sparing amount of grease on the gears and surfaces. Here’s what we picked up on after our first two winch cleanings:

- The winch components were full of dirt, hair (PO had a dog on board), and old grease caked on. This was particularly hard and messy to clean up. I used PB Blaster and WD40. I think the WD40 was more helpful, but we needed to find something a little better than this.

- I purchased some cheap aluminum tin trays from the grocery store to put clean and dirty parts on. These were fantastic.

- It was messy using a stainless brush on the parts to clean them. It would be much easier to have a bin filled with mineral spirits and soak the parts. Rather than spraying them out in the open and brushing them like I was shining a fine pair of leather wingtips.

- The spindle bearings were not installed correctly with the spacer on the bottom, so we corrected that on the re-assembly.

- We need to do a better job of cleaning the frame before re-assembly. We didn’t pay enough attention to bearing surfaces and getting them perfectly clean.

Next time I will take out the rest of the thru-hulls, remove the propeller to prepare to install the cutlass bearing, and removal of the Webasto diesel heaters which are attached to the underside of the cockpit hatch.

For now, I’m warm and cozy in my garage taking measurements and getting my shopping list ready to go.

There are so many activities to keep track of during this time:

| Vendor | Purpose |

|---|---|

| Bauer Compressors | Rebuild parts for the dive compressor |

| Blast Lab | Powder coating for the dive compressor frame and Lewmar steering frames |

| AB Small Engine Repair | Tune the Honda engine for the dive compressor |

| Mauripro | New Lewmar steering bevelhead and u-joints |

| HR Parts | New pressure tank, new elk hide steering wheel cover, new cutlass bearing (35mm shaft) |

| Mack Sails | They are making our new sail bag and new lazy jack lines |

| Quantum Sails | They are cleaning and repairing our main sail |

| Miscellaneous (eg Amazon, West Marine, Defender) | Volvo shaft seal, oil filters |

OK, that’s it for now. Next time, more cutting and disassembly. We know the weather will be inhospitable for the next 6-8 weeks in Connecticut, so our expectations are low for high productivity.

Bonus: We’re preparing our family for a life aboard. Here our youngest son is taught how to rotate tires on our truck. Boats don’t maintain themselves, and kids need to learn how to work with their hands at a young age. Thanks for reading.