We completely renovated all of the removable generator panels, finally. This was a project within a project. In total there were 7 removable panel pieces that had extensive rust and paint removed from an unattended leak from previous owners. The generator sits on the outer starboard side of the engine room. Above that location in the cockpit lazarette sits our hot water heater. The water distribution manifold is also in the lazarette, and we suspect leaks from that manifold were dripping down through the lazarette door (which has several cracks in it) and onto the generator. We have other theories as well about how water was leaking onto the generator, but nevertheless, we had a lot of rust to contend with.

There are two ways to do this. 1) Buy all new panels from Cummins / Onan or 2) Media blast and powder coat the existing panels. Cummins / Onan doesn’t have these panels in stock and cannot make them for me, so that option is very low. So the only path we have is to have these panels re-painted. Media blasters don’t like glues and paper getting into their spent media collection systems, so we have to get all insulation and labels off the panels. But if I did that, how was I going to re-create these labels since the removal process would destroy them? Cummins could not generate the labels and send them to me.

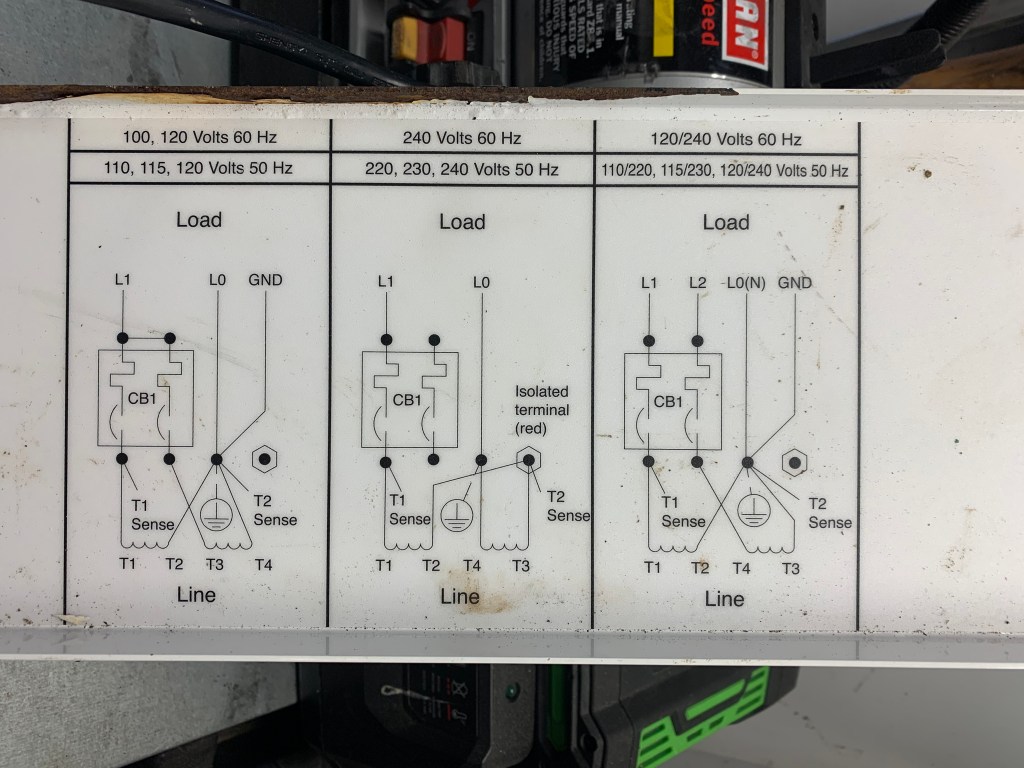

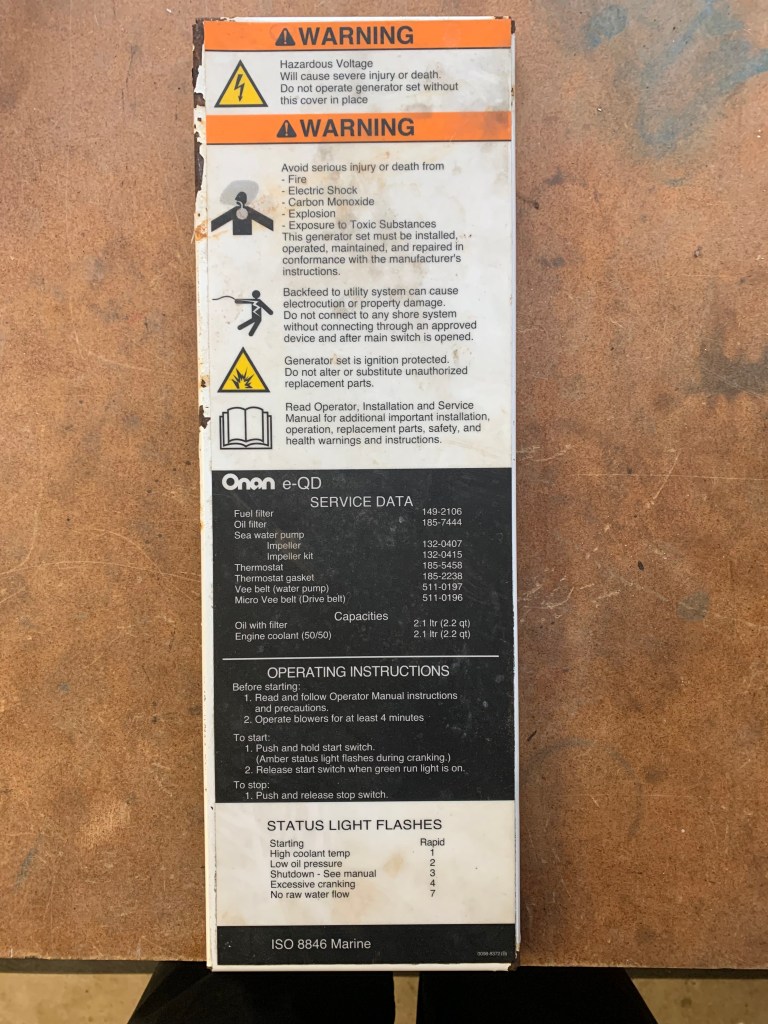

I carefully peeled the labels off the panels. Then I took them down to a FedEx Office location, and made a high quality photo copy of them. They have a process whereby they take a print and laminate it into vinyl sleeve which has a sticky backing. Voila! I have like-new labels for the generator panels.

Once all of the sticky glue and flaking insulation was removed from the panels with scrapers and Goo Gone, I took the panels to Chesapeake Coatings. Chesapeake Coatings is a high volume shop for fencing pipe, and other large items that arrive on pallets to their shop.

These guys have a serious business and very little time for a pesky and detail-oriented engineer with 7 small panels. So I am careful to not get too fancy with them on trying to pick the colors (hopefully it matches to the Onan original color) and timing. It took them about a month to squeeze me into their schedule. To my surprise, the panels look fantastic and the color match is very good all for $200. Not bad!

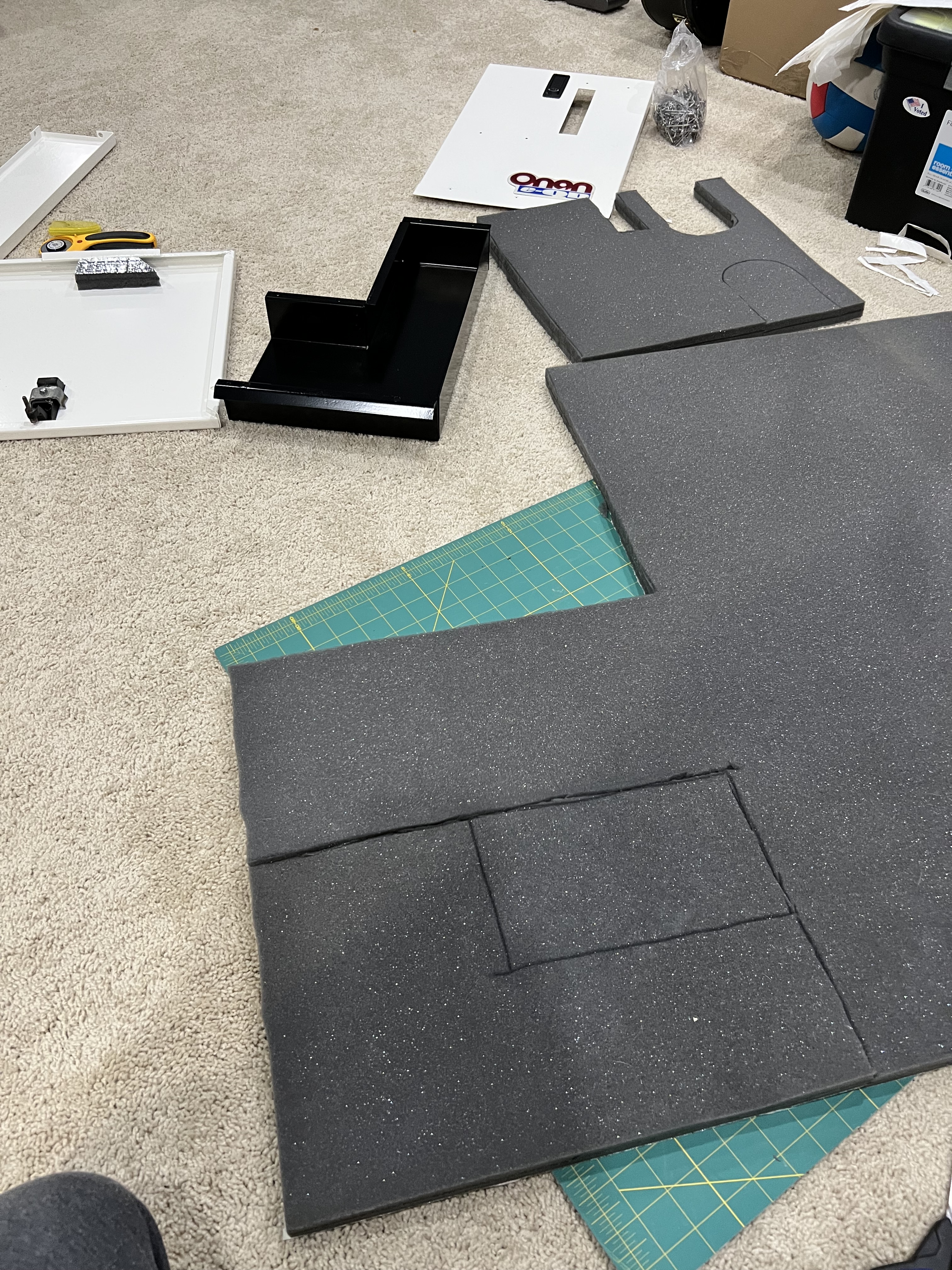

The last thing is to glue in new sound insulation purchased from Defender, to re-install the hardware and rivet parts together. The insulation was a little bit thicker than the previous Onan insulation, and the new insulation was multi-layer with a thick plastic (?) layer sandwiched in the middle making it painful to cut.

I think the panels turned out very nice and highlighted by our new LED lights in the engine room thanks to Ray.