Deck – Osmotech has started putting down caulk and trim pieces. It is starting to come together quickly. The sanding should be done by the end of February, and the hardware will go on in March. That means I have to get busy finishing projects.

Some things I really like so far are: Edge trim pieces are epoxied to the adjacent wall/structure instead of being caulked. Stips are butted together lengthwise with epoxy instead of having a caulk seam. The original butt-joint caulk seams tended to rip out under shoe while sailing. Osmotech also removed our sprayhood in order to replace the teak in the cockpit area. We are learning a lot about how the boat was constructed as we observe the progress of the job.

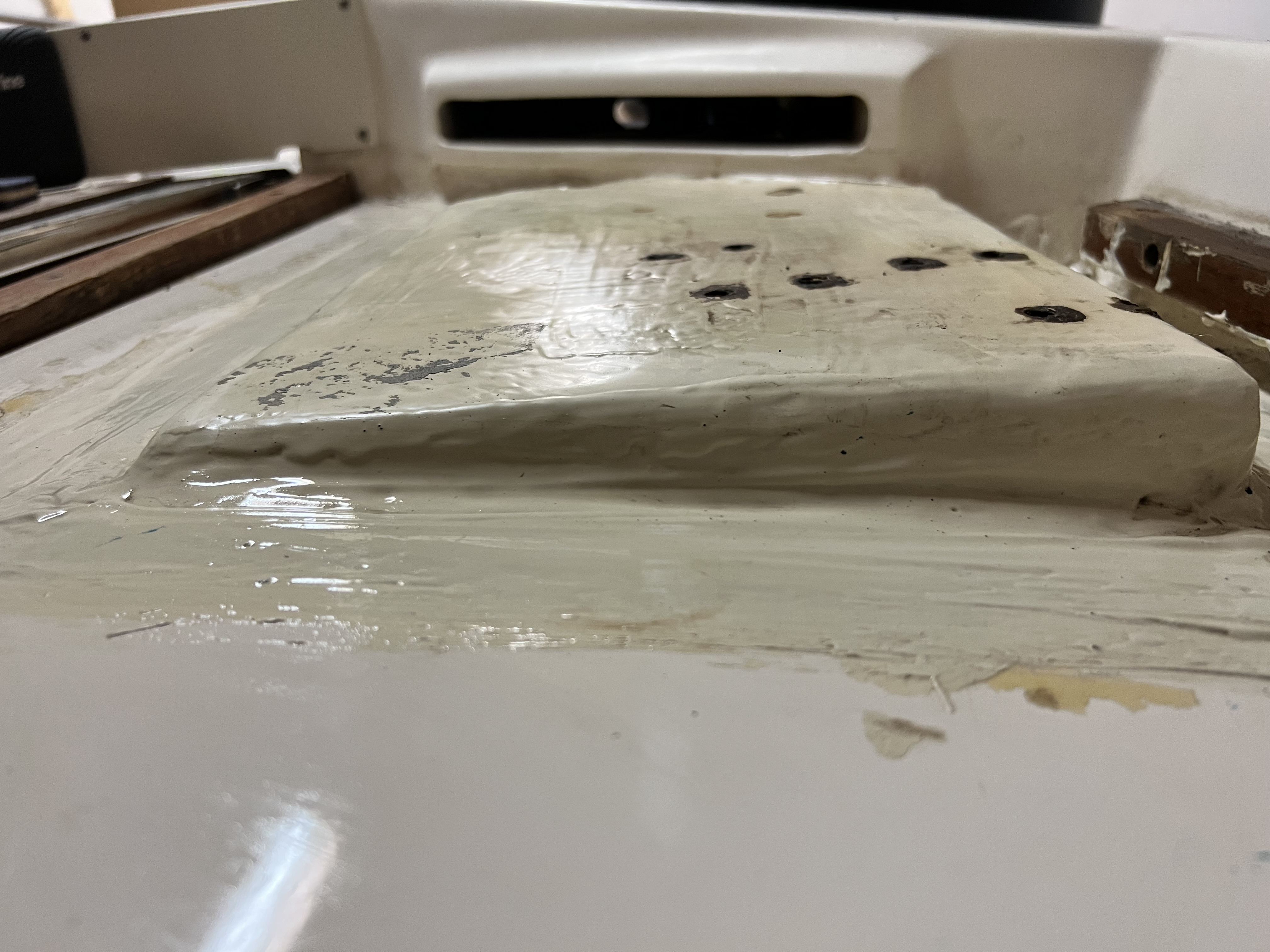

Companionway – I removed the “chart tables” on the companionway so that I could sand and re-varnish them. Recall that we have our main sheet, vang and reef 1 + 2 lines lead to the cockpit. This was a customization done by a previous owner which we like but also have to become more accustomed to. The lines lead into the cockpit to which we have a custom-mounted electric Antal W48 winch mounted on the cockpit gunwale. If you have an HR sailboat and want to bring your lines into the cockpit, here is a detail we found underneath the starboard chart table.

We have two rope clutches mounted here to secure the sheets coming from the mast. Those rope clutches are secured to a custom-built fiberglass base that is tucked underneath the chart tables.

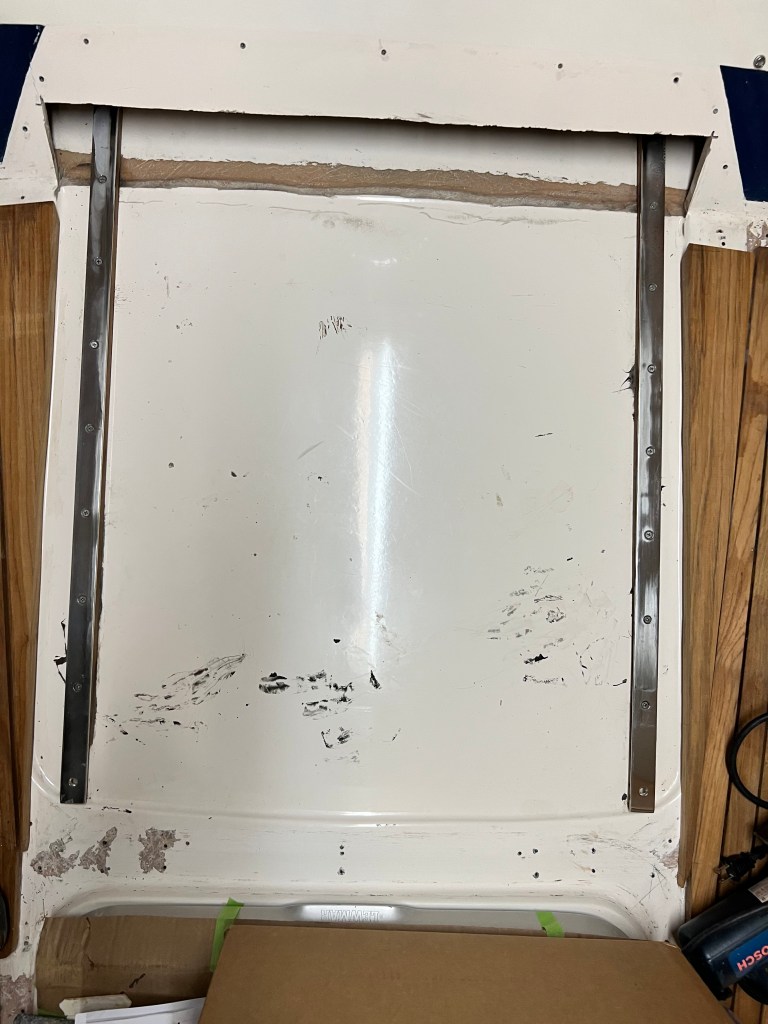

We cleaned up the companionway hatch slides. The slides are stainless steel and had only 1 or 2 screws each securing them to a strip of scrap teak that appears to be expoxied to the deck. The hatch didn’t slide smoothly. I degreased the slides and then applied some dry lubricant to the slides.

This was the perfect time to do this maintenance since the companionway hatch cover is removed. I’ve been wanting to improve the slide since we bought the boat.

Wheel – Finally, we finished off the wheel with blue-suede leather from boatleather.com and three turk’s head knots. We cannot wait to put this on the helm.

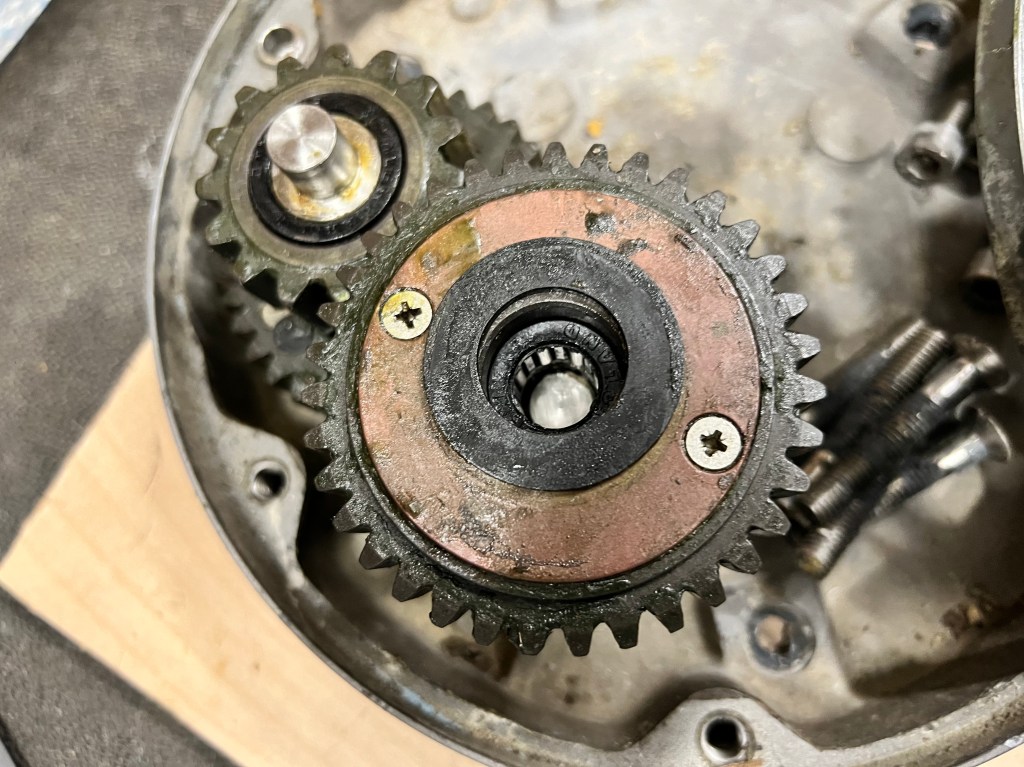

Winches – All manual Lewmar winches have been maintained with full removal of all grease, dirt and grime. I used shallow baths with mineral spirits and cleaned every part with a bronze or steel brush. Now we have 2x66ST, 2x44ST and 2x40ST Lewmar winches fresh and clean, all complete with new pawl springs.

The winches were all very dirty and sticky. Most of the pawl springs were compressed and “glued” shut, and the gears were all very heard to turn by hand. The work is done for now, and now we hear crisp click-click sounds.