The teak deck work is now 100% complete, and the deck hardware is now being installed. The mast being stored at Bert Jabins has had most of the work done to it already. We are getting close to finishing off several key projects and many small ones. Skyward is ready to get back to sailing very soon.

Deck – We absolutely love the final product. The deck was completed last week with final sanding done on 08 Mar 2023; that is just short of 4 months to the date of dropping it off. As it was reported, all of this work occured while Skyward was in the water on a floating dock in Annapolis. With the deck completely sanded, chiseled and detailed, all of the creativity and craftsmanship jumps out at you. What I like especially are the butt ends are epoxied together as opposed to having another caulk joint.

I will upload pictures in the next blog post showing the hardware installation. But the Osmotech team with Micah, Chico and Barry have done an amazing job. As they cored the deck to install fittings today, I kept one of the pieces and measured the sanded thickness. It was nice to see a full 1/2″ thickness with 100% penetration of caulk.

Mast – I installed a like-new Lewmar 90 mm synchro spinnaker block to replace the UV damaged and corroding one that was there already. All new running rigging, all new main track, a new radar bracket and new steaming/deck light combination have been installed. I assembled all 5 mast-mounted winches to their bases that have been fully cleaned and prep’d – 3 x 44ST, 1 x 16ST for the outhaul and 1 x 8 for the spinnaker car. Finally, all 13 Selden main cars were carefully installed leaving only a few details left to address. Next week, we start the rigging build.

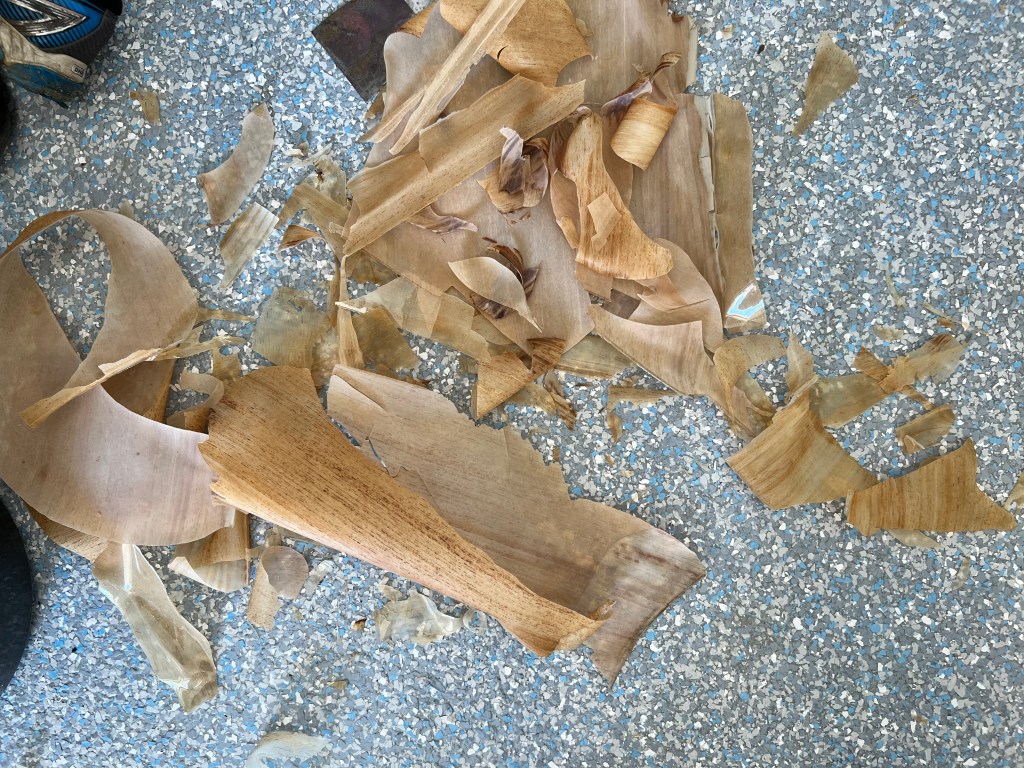

Chart Tables – I removed the chart tables which had been coated in a polyurethane or epoxy that was yellowing and falling off. I heated, scrapped and pulled on the coating and it came off in large pieces. The port table contains our chartplotter and our forward-looking sonar device. The startboard table contains two pairs of dual cleats for the main, reef 1, reef 2 and vang lines that are routed to the cockpit from the mast. There are dark stains and slight wood surface irregularities related to these items which were directly installed on these tables.

I cleaned the tables with #2 Snappy Teak to attempt to event out the finish. I used the Snappy Teak brush and kept the surface wet the whole time then I rinsed the surface and let them dry in the sun. Once dry, I sanded the chart tables lightly with 220 grit and 4″ orbital sander then finished with a small sanding block. After wiping down with a moist rag and letting them dry fully, I applied the 1st coat of Epifanes diluted to 50% with acetone. That consumed about 9 oz of solution for the record.

Pulpit Seat – The pulpit seat has been sanded and now has about 6-7 coats of Epifanes on the top with a couple of coats on the bottom. Ready for installation as soon as possible!

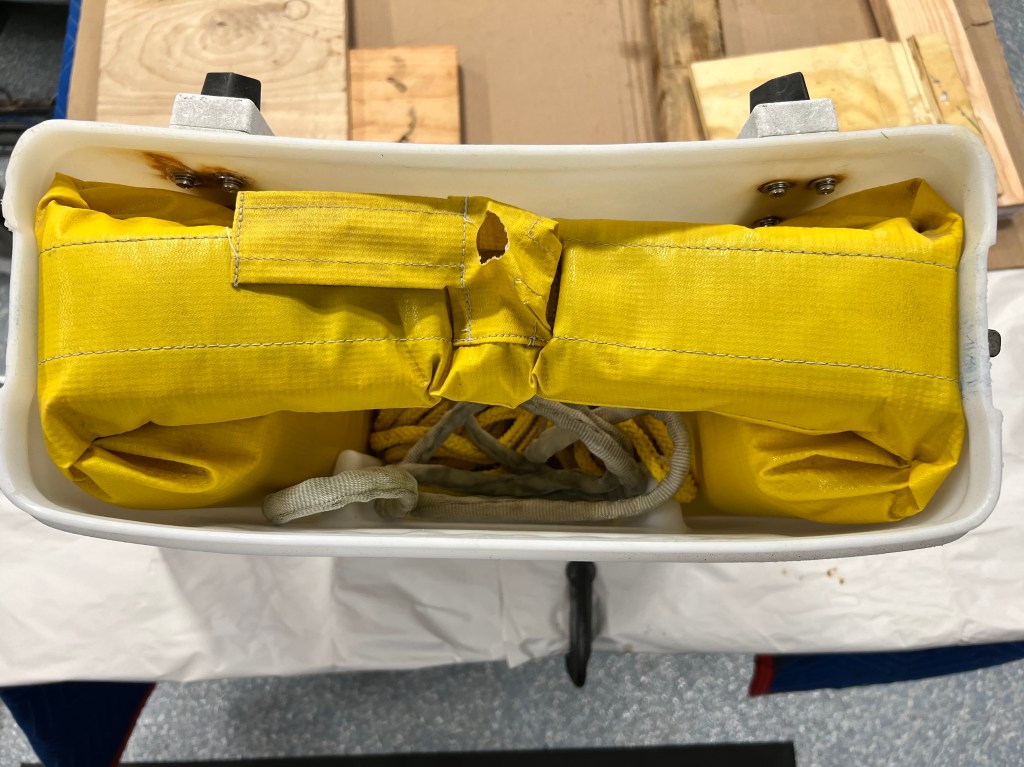

Liferaft – I am a bit disappointed with Citimarine who sold me the liferaft. The unit came with the wrong nameplate information (it was listed as already being 1 year old and due for inspection almost immediately!) and the strapping was not correct as it did not support the Hydrostatic Release Unit (HRU) properly. They gave me almost zero support, so I contacted Viking directly and they have been somewhat helpful. I want to be pleased with the purchase since it was very expensive, but when both the company and the distributor do not get it right even after multiple attempts of me explaining the situation of what is missing they have not yet crossed the finish line. I will keep following through on this and report back.

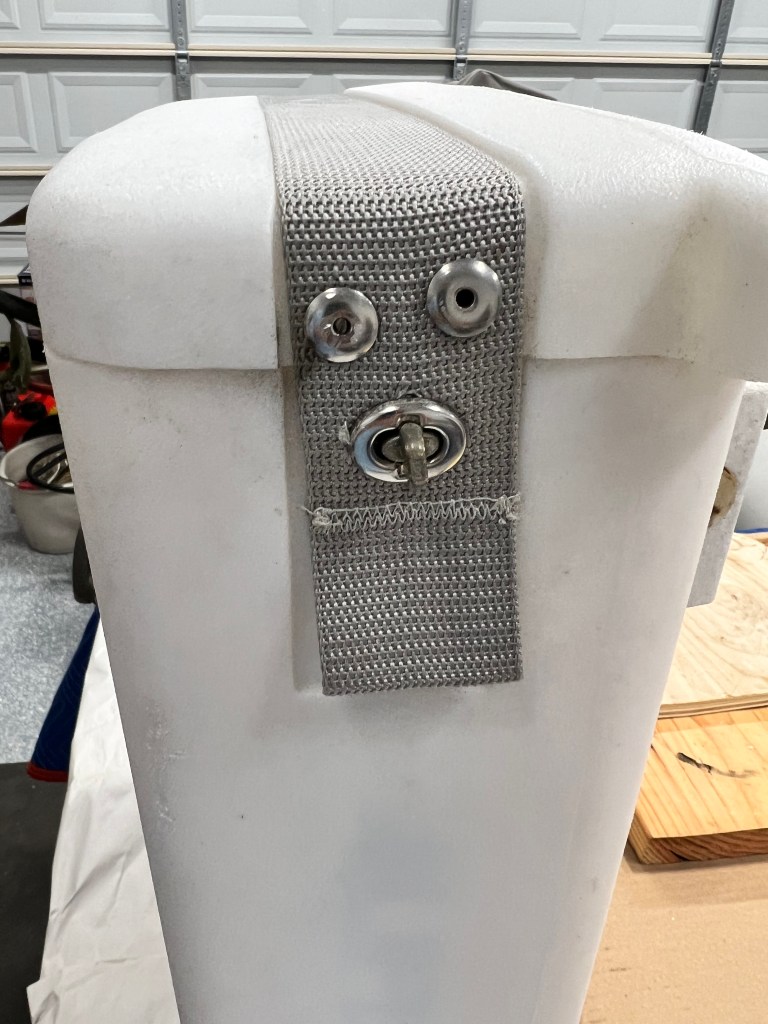

Lifesling Box – I got a little too detail-oriented with this project, but I went for it anyway. I replaced the hardware which had rusted on the inside of the box. I also replaced the 2″ strap and installed new rivets and the whole 9-yards. This was interesting as most off-the-shelf rivet tools cannot properly secure a 3/16 steel rivet. I also cleaned and hung the lifesling safety flotation device to dry. All ready for a few seasons of at-ready service and sitting in the sun.

Dinghy Motor Mount – Ray is building us a new teak dinghy motor mount like he did for Cloudy Bay. I am really excited to remove the original Edson which doesn’t fit well and it a little too tall. This is starting to come along quickly; that’s how Ray works his magic!

We will have at least one more blog post devoted to the deck and all hardware being installed. For anyone still reading, I must say that we have had almost zero dust penetrate the interior of the boat; the Osmotech team did a bang-up job sealing every vent and hole. Stay tuned!