This Winter has felt more like work on Skyward rather than sail Skyward. We’re very much ready to get on with the sailing season, and pretty much “over” boat projects. And if you’ve been following along, you are probably saying the same thing. But we all know that the list of boat projects never ends.

It has been almost 6 months to the date when we took down the rigging and parked the boat at Liberty Marina. Though it would have been nice to just drop off the boat and not see it again for 6 months, I can assure you the time has been absolutely filled with a lot of work and 100s and 100s of decisions. There have been many nights out and back on the floating dock at Liberty Marina peeking in to see the progress. This all occured through the holidays and some intense work activities — i.e., land life. One of the things we did was to completely empty the boat from 25 years of stashing and stowing with all mattresses removed, all spares, anything except my tools. It alike have been painful to do that in a foreign country with the advantage pf seeing everything and putting only what we want to back on the boat.

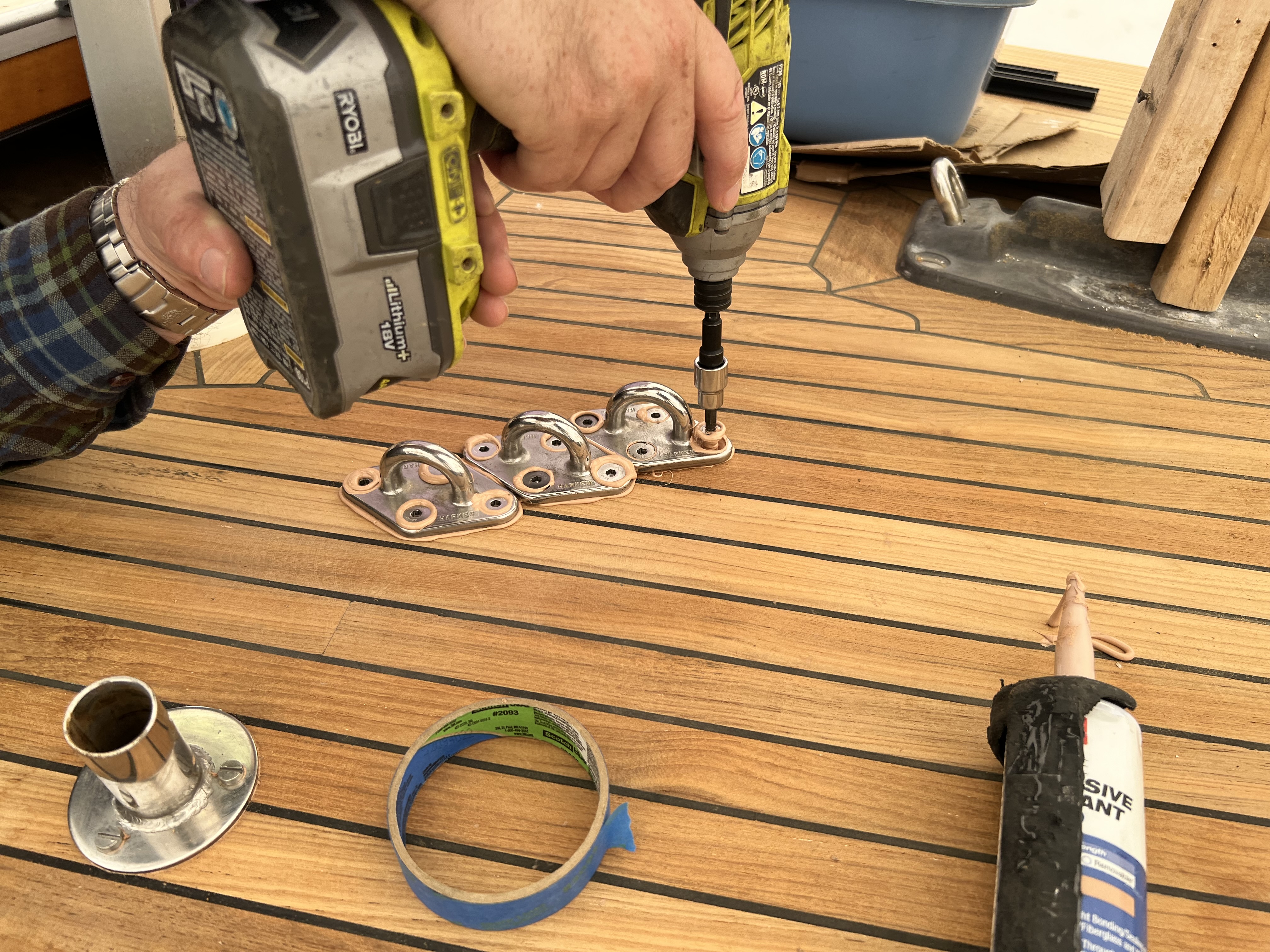

When we started the project, I remember Marty from Osmotech making the comment that people sometimes spend a bit more than the deck replacement budget because they want to refresh things a bit. Boy that was an understatement! I did not expect to replace so many deck fittings and various hardware bits, but my mindset was that if I was ever going to replace these items, this is the time -and- why would I re-install shabby 25 year-old hardware on a brand new deck? You set a budget for these things, and then there is reality. But we learned from this to order as early as possible due to supply chain issues and that things aren’t getting cheaper.

We don’t approach these types of projects and decisions in life often and we don’t do so without some deep thinking and evaluation. We have goals to sail off into the sunset, but we also know there are a lot of easier ways to do this. Sure, buying another boat that is already well-sorted sounds like a good idea, but that would mean a large loan and monthly payment which would not be desirable. And certainly, a newer boat or one that would need less work wouldn’t necessarily mean that I would be an “arrive-and-sail” kind of owner. We all know that every boat has its problems. I didn’t want to miss out on building a deep knowledge and confidence in the boat that we intend to sail far away, so we took this approach to refit Skyward. We made sure of that by taking on several maintenance and replacement jobs this Winter.

By October 2022, I would say that 25% or more of the deck screw plugs popped off and the majority of those were paper thin already. The deck caulk was missing about 10-15%. Both the plugs and caulk were getting worse each week with generally walking about, and it was clear to me and to our trusted friends that we would either have to sand down, route all edges, remove all screws, and re-caulk the entire deck or replace it. Otherwise, we would be risking the layers of the deck from getting wet due to leaks. We researched teak vs. faux teak and came to the relatively fast conclusion for us; Decision #1: Replace the teak deck.

The rigging was from 2006. Decision #2: Replace the standing and running rigging. It made sense to us to do these two major projects at the same time so that the deck replacement would be more efficient.

I’m jumping to the end with this thought, but I realized too late that while I spent a great deal of time on the teak deck side of the refit, I didn’t spend enough time on the rigging side. I enjoyed working with Micah. I didn’t get into his way on how the teak was being shaped, laid or caulked, but he and I worked together on the hardware installation. It was a great feeling of accomplishment to see it all come together. But the mast and boom needed more attention than I was giving them. The truth is, we should have devoted additional budget to the mast and boom to plug holes and protect the mast from future corrosion.

Once those two decisions were in motion, it was as if the sails were set and we just had to hold fast. With the required down payments made, the contractors started getting busy ordering parts and beginning work. I also did the same to tackle my own list. I worked very closely with Mauripro and HR Parts for deck hardware, but I found myself in Ace Hardware more than I anticipated trying to find that one screw.

Here is what has been completed since November 1, 2022:

| Category | Description |

| Deck | Replaced the original teak deck with new teak deck to a final thickness of 12.5 mm at a minimum. All butt joints are epoxied. All teak-to-fiberglass connections sealed with 5200 (not caulk). |

| Bits on Deck | Replaced the diesel fill, water fill and 2x waste deck fittings Replaced the aft shower deck fitting as the original one was damaged Replaced all seven original dorades and fiberglass boxes with AirOnly vents Replaced the windlass foot pedals on deck |

| Structure | Added more structural support for deck-mounted blocks for lines running to the cockpit Added more structural support for the granny bars at the mast with 2 out of 3 legs thru-bolted |

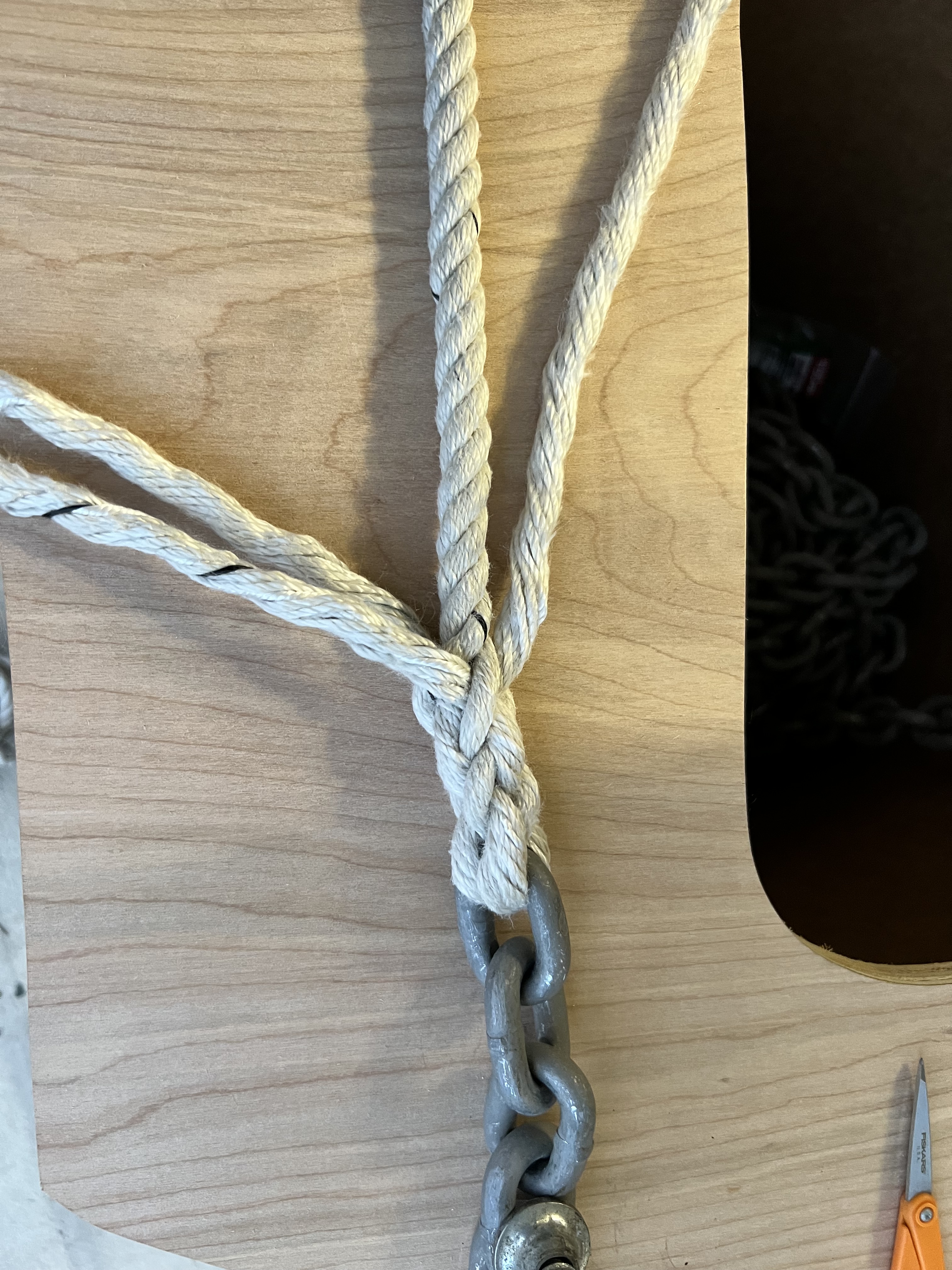

| Anchor | Installed a new 35 kg Ultra Marine anchor and swivel Replaced and beefed up the anchor shelf (again) with 1″ thickness of marine ply with several layers of epoxy and Bilgekote Replaced the anchor chain with 250 ft of 3/8″ galvanized HT chain with 75 feet of 3-strand rode spliced onto the bitter end of the chain Cleaned, sealed and painted the anchor locker Replaced the bow roller on the starboard side with a new one from HR Parts (shortened properly by Ray on a lathe) |

| Safety | Installed a new Viking RescYou 6-person liferaft with HRU Renovated the Lifesling box that sits on the pushpit Cleaned up the MOB pole by epoxying the loose strands and added a flag Replaced the PA speaker/horn with a new unit Installed a new EchoMax 305 passive radar on the mast |

| Brightwork | Refinished the dolphin seat on the pulpit with Epifanes gloss Refinished the companionway chart tables with 6-7 coats of Epifanes gloss |

| Winches | Rebuilt all winches on the boat and mast; 12 total. (11 Lewmar and 1 Antal) |

| Sails | Cleaned and repaired the North Sails genoa Cleaned and repaired the Elvstrom jib Cleaned and repaired the hank-on Elvstrom staysail |

| Deck Cars | Replaced all components of the main traveler system with new Lewmar Size 2 track, car, end stops and conrol line eye-spliced to the end stop beckets with 5:1 mechanical advantage Replaced all components of the genoa/jib systems with all new Lewmar Size 2 track, cars, end stops and control lines eye-spliced to the end stop beckets. |

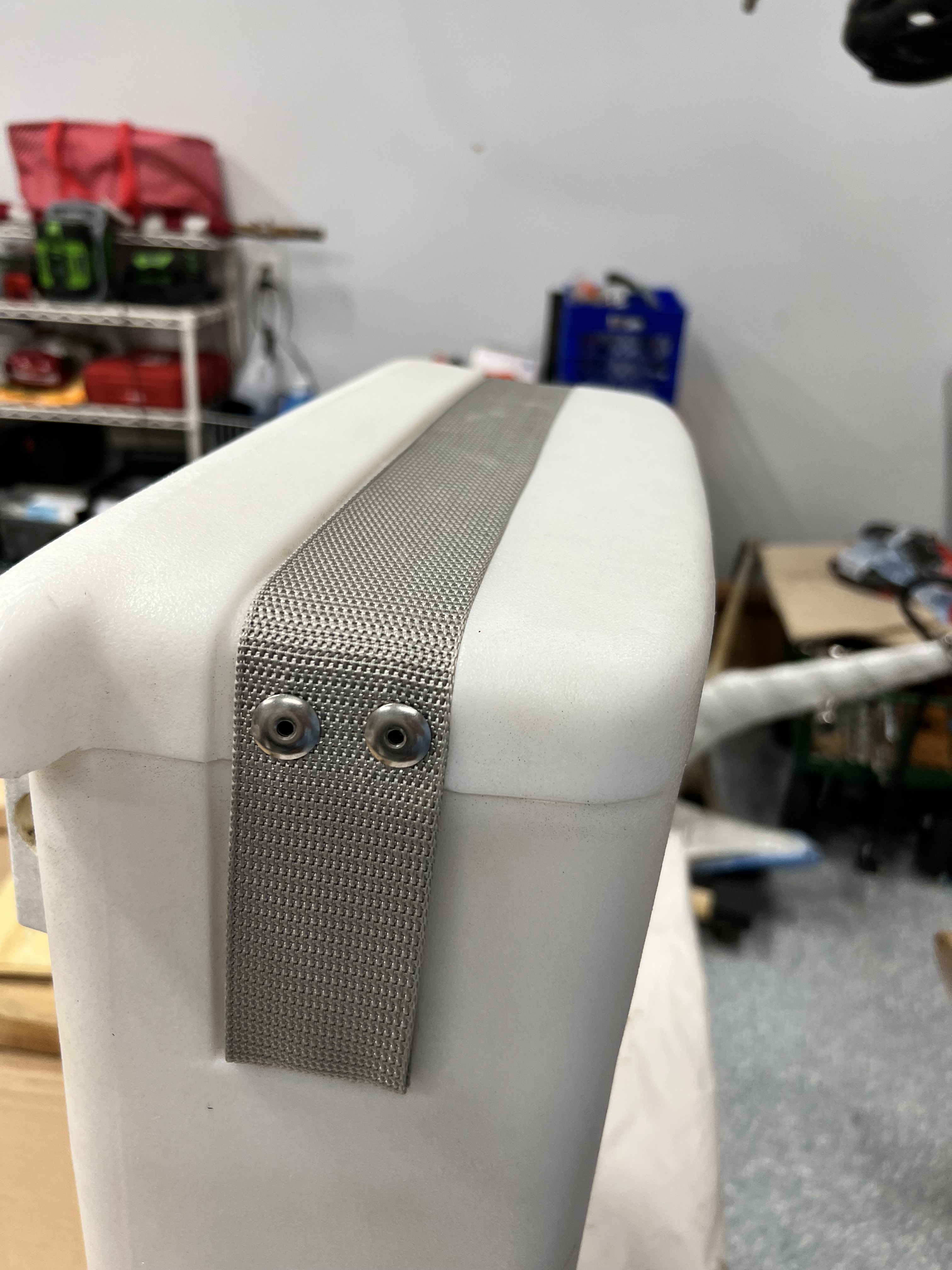

| Comfort and Convenience | Added a winch handle pocket near the helm Replaced the TV with a 32″ Samsung monitor / smart TV running on 230V Replaced the steering wheel leather with new leather Replaced the solar panel edge guards which had deteriorated since purchasing the boat Apply Fiber-lok non-skid backing to the carpets as the original backing has almost entirely deteriorated Refinished four main salon floorboards which had taken a beating by the deteriorated carpet backing Waterproof the sprayhood and sprayhood extension Installed a new galley faucet from HR Parts Installed new porthole curtains Replaced the Edson dinghy motor frame with a solid teak wrapped in stainless |

| Rigging | Replaced all standing rigging from 2005/2006 from pin-to-pin Replaced the radar bracket on the mast with a new one from Kato Marine Replaced the forward lighting on the mast with a combo deck and steaming light Replaced the main Selden sail track on the mast Replaced the 90 mm spinnaker halyard block at the top of the mast Installed all new wiring in the mast with chafe protection at the openings Waxed the mast Replaced the genoa furler with a new Selden Furlex 400S unit Replaced all running rigging Installed a single set of spreader lights |

| Mechanical & Instrumentation Maintenance | Cleaned generator heat exchanger and replaced the flow sensor Replaced the Airmar speed and temperature sensor Rebuilt the windlass top end Fixed the companionway hatch slides which were loose and not secured well to the coachroof Replaced a scupper drain hose that seemed to be too short (as the deck raised up, this hose could not reach the fitting) |

Ray helped me move the boat from Liberty Marina to the dock at Bert Jabins Yacht Yard. It was a very peaceful day, but we were caught off-guard by how low the coolant was. I think I burped it during the winterization, so we filled up the coolant and vented out any potential airlock and we were on our way. It was a quick 2 hour trip up the Bay.

Now we are waiting the mast stepping and rigging install. In the meantime, I am working on cleaning up the pedestal switches and autopilot controller. If there is anything that you would like me to take a deeper dive into, let me know and I would be happy to write a short post about something you are interested in.

Here are some final pictures from the end of this refit:

Here’s to everyone having a safe and enjoyable sailing season in 2023!