We started smelling something foul from the faucets any time that we turned on the hot water. The hot water system wasn’t heating from the electrical panel for some reason, and I think we had the coolant lines from the engine air locked. It was time to pull the tank out and investigate and repair. We have a Sigmar 40 Liter EG Inox 316 Stainless Steel tank with an internal coolant coil which heats the water from the engine coolant and also an internal heating core with thermostat for electric heating under shore or generator power.

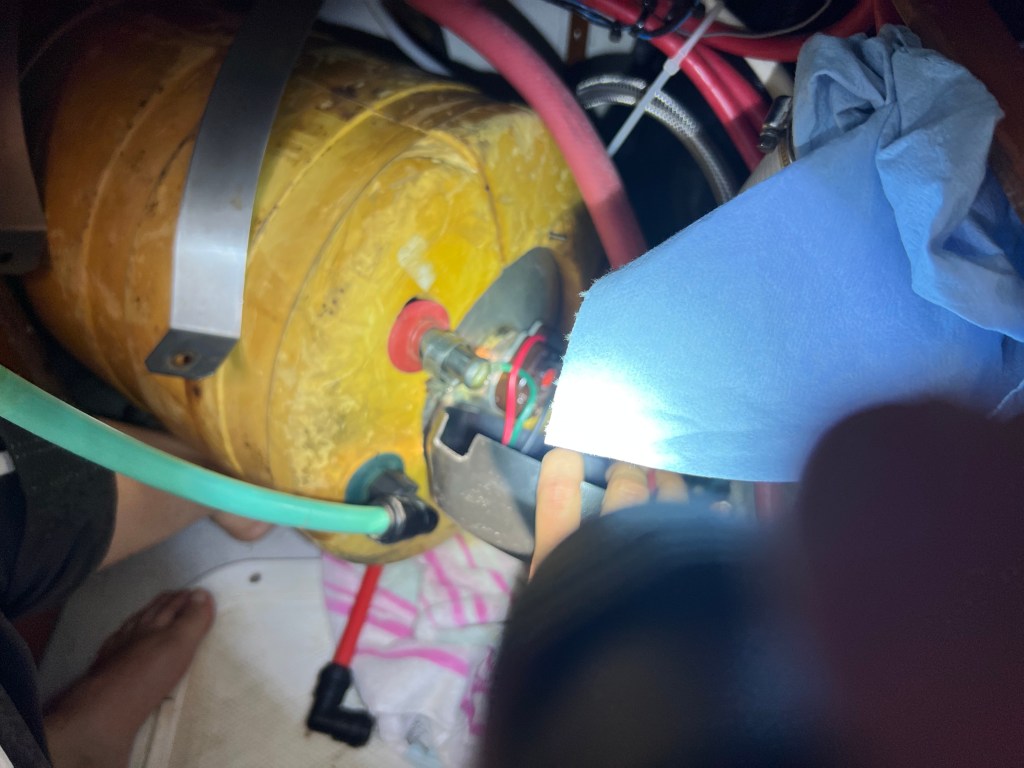

A previous owner must have decided to move the hot water tank to the cockpit locker and place the aft holding tank above the generator in the engine compartment. That isn’t necessarily a bad thing, except no one oversaw the contractors doing the work and the contractors didn’t install the tank in a manner that allowed good access for maintenance. The heating coil and thermostat could not be replaced without completely pulling out the tank.

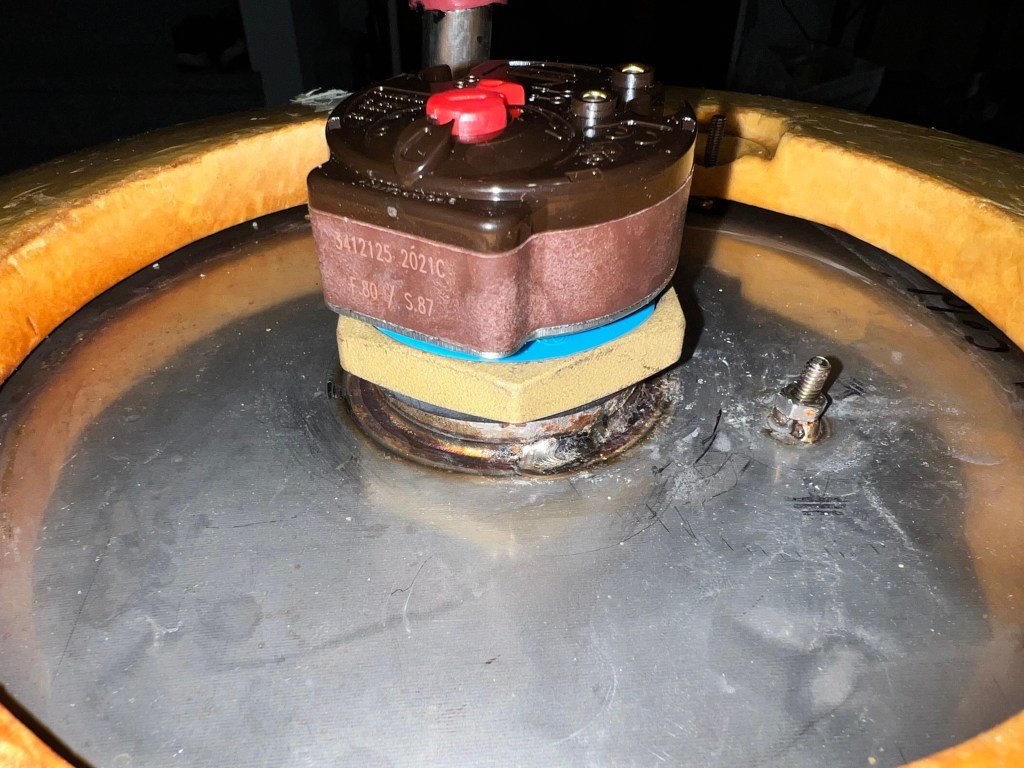

We found some corrosion around the heating coil and thermostat connections as soon as the tank was wiggled out of it’s tucked-away position mounted fore-aft in the cockpit locker. That was not a fun job…glad that Rachel decided to tackle it!

We could look down into the tank and see sludge build up on the bottom and biofilm was clearly present. We tried to rinse it out, but it was not coming out. Because the stainless steel tank was fully welded without flanged heads, the only access is about a 2″ threaded nozzle. We knew we could not mechanically scrub or even agitate any solution.

Having a lot of experience designing, building and operating Clean-In-Place (CIP) and Clean-Out-of-Place (COP) systems for the biologics/pharmaceutical industry, we decided to apply a soak approach to clean out the biofilm. Our research showed that Tergazyme is an enzyme-active powdered detergent available for retail sales and which is used to clean biological substances by breaking them down. You can’t simply put bleach on sludge and expect it to clean it off, because parts of biological sludge/biofilm are hydrophobic, and therefore limit the effectiveness of bleach solutions.

We ordered and picked up a box of Tergazyme in Hanover, MD (from a tattoo equipment distributor of all places!), and mixed about 2% by weight to 130 deg F tap water to fill up the tank to the top of the nozzle.

I rocked the tank around to mix the solution the best I could and I used a long shank flathead screwdriver as a hand mixer. We let this sit for about 3-4 hours. I drained the solution and then pressure-rinsed with cold tap water from our spigot at home. I held the tank upside down vertically while Rachel turned on the pressure wand and rotated it 360 degrees and moved it up/down the tank on the inside. I would have added the powder differently next time by pre-mixing in a concentrated solution, because I got out a number of undissolved chunks of powder when I sprayed the tank.

Nonetheless, the result is amazing!

We had planned to do: 1) Enzyme soak to loosen the biofilm -> Rinse, then 2) bleach soak to kill remaining bacterial growth -> Rinse, then 3) Citric acid passivation -> rinse. Based on the cleanliness after the enzyme soak, we decided to skip the bleach and passivation.

I installed the new heater coil and thermostat that Ludvig sent to me last year from HR Parts. This tank is ready to go back into service.