We had an inspired and ambitious sailing season planned for 2023. After visiting St. Michaels, we wanted to go to Solomon’s Island and make another stop along the Eastern Shore during the 4th of July weekend. That was supposed to be followed by a trip to Gibson Island for an overnight anchorage. None of these happened all because of a mistake which lead to a shortcut that I took. Then I’ll explain another shortcut that I took to get back out on the water.

short·cut noun an accelerated way of doing or achieving something. "they were taking a shortcut to town"

With sailors come strong opinions. I am one that believes in shutting as many thruhulls as possible whenever we leave the boat for an extended time. For example, after a weekend of sailing, we button everything up and we don’t come back until the next weekend. We learned some lessons when moored at Atlantic Highlands that the weather can wreak havoc on a boat left in an unprepared state. And if you have read in our earlier blogs, I took a lot of pain to re-engineer our engine bay and thruhull arrangements which included relocating and installing new thruhull/seacocks and new strainers.

Picture this: It is Saturday morning on the weekend before 4th of July which is midweek, and every boater in town is on the water. Back Creek looks like a traffic jam especially at the entrance point. Here comes Skyward starting a multi-day excursion motoring under the strong Volvo TMD 31L-A passing the Annapolis Landing fuel dock when suddenly the high temperature alarm goes off. Boats are coming at us from the front and the rear like traffic on a super highway.

Unconciously, I scanned the area and saw that we had shallows on starboard, docked boats on port, and other craft within 2-3 boatlengths away from us moving at a steady 5 knots. The temperature of the engine was slightly above 200 deg F according to the gauge on the panel. All I wanted to do was to stop the boat and get out of traffic. I will say that my language and tone of voice changed instantly, and to be honest, I was panicked because time was not on my side.

Due to the precariousness of the situation, we didn’t have the luxury to take alternative measures like raise sails to use wind to get moving or drop the dinghy in the water to push/pull the boat. So I decided to use the bow thrusters to turn the boat around without using engine RPM. We “limped” back up the Creek towards the fuel dock under low RPM and dropped the hook quickly (about the same location as the sailboat in the picture). Since I normally do the anchor work, I was also dealing with inexperienced crew (family) working that part of the boat.

Even after the hook was secure I wasn’t becalmed; I didn’t want to risk dragging into the $million boats docked nearby without an engine to pull away. I was initially focused on figuring out how to get the boat back to our dock which was less than 0.5 nm away. My head was laser locked on this; get the boat home and “rescue” the family from this mess.

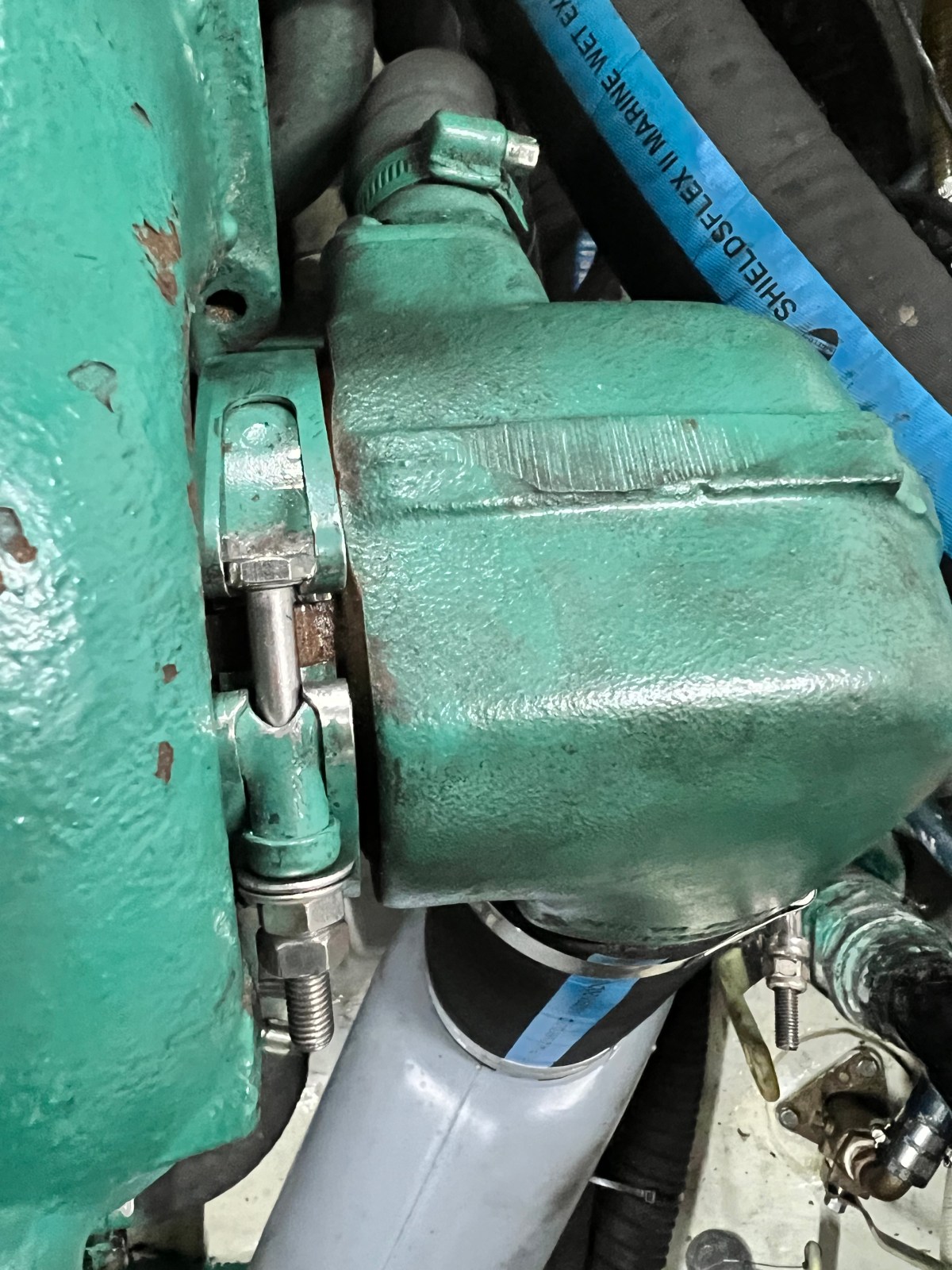

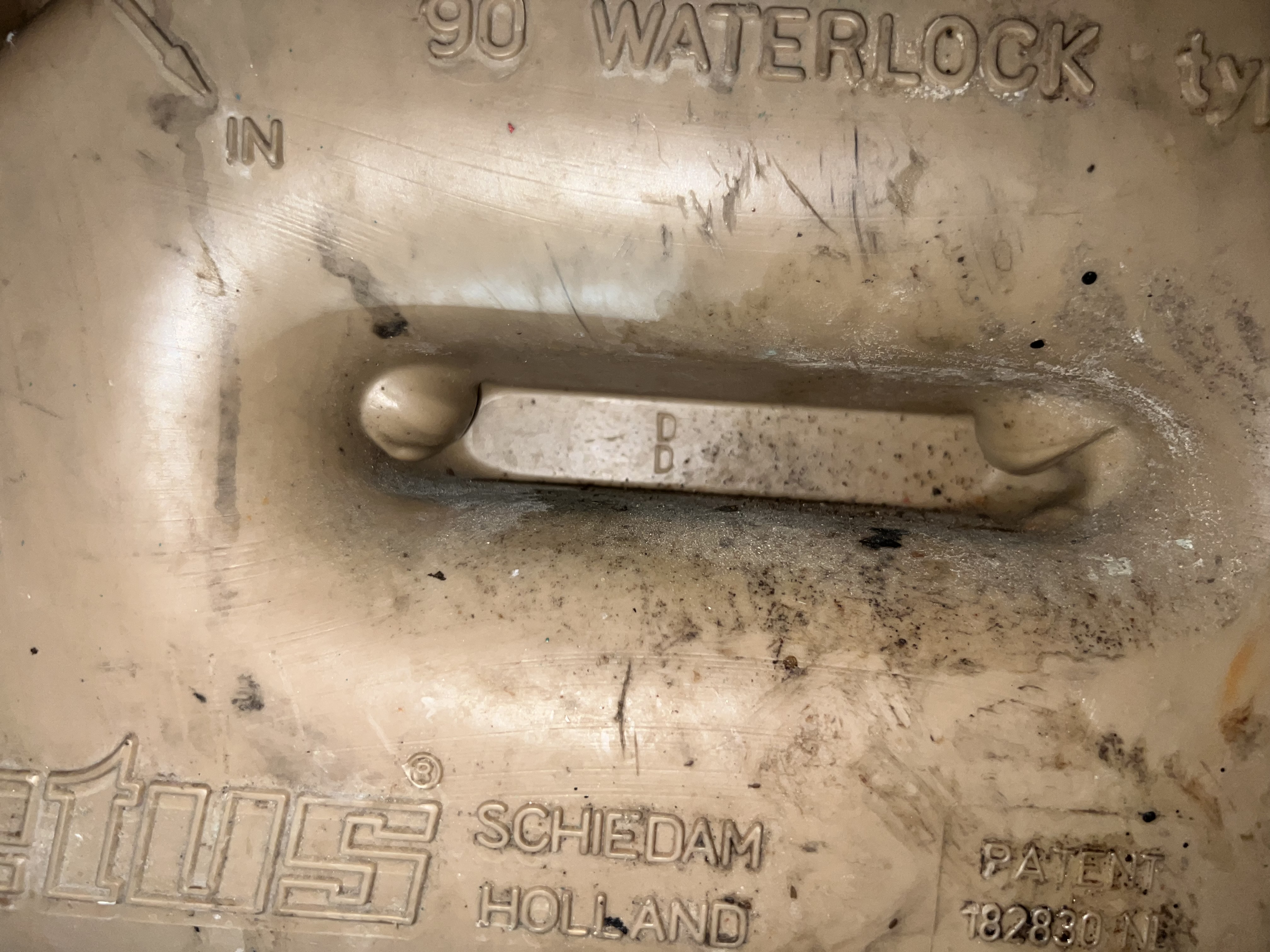

After a few minutes, I cooled down (slightly). After restarting the engine again, the kids were yelling “there is smoke in the engine room”. Turn the key, go down below. I peeked into the engine bay, and immediately saw that water was coming out of the Vetus muffler. It melted under extreme heat and created a hole which I could not see but I could feel water flowing out of the unit on the backside.

It didn’t take me long to solve the formula: Someone (me) forgot to open the engine raw water seacock! My mind did double-time recounting all of the steps that lead to that realization. We shortcutted the normal steps that I take to leave the dock. I was pre-occupied by watching the crew handle the dock lines, and I made the assumption that they released then before I was ready at the helm. That caused me to motor forward and get us moving away from the dock too quickly.

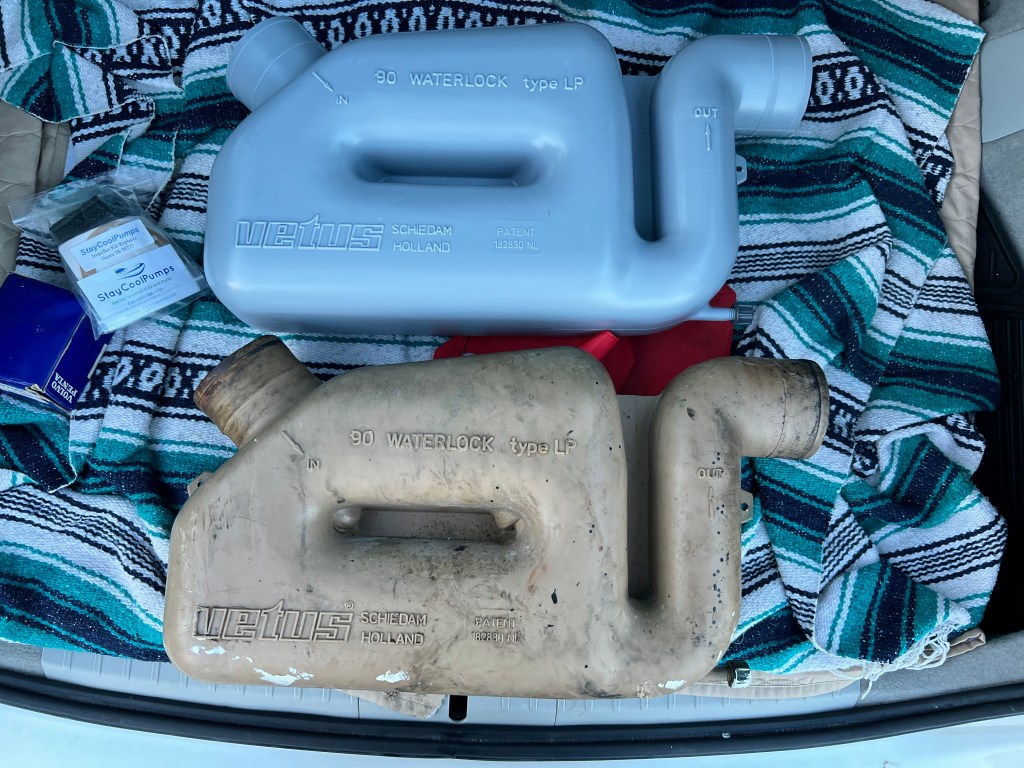

Back to the situation at-hand. It was just after noon time. We were all getting hungry but we pressed onwards with some delerious idea that we could still salvage the weekend plans. So we called every marine store in the area seeking a replacement muffler. West Marine – no. Fawcett – no answer (of all places, we thought they could help us). Bacon Sails – they weren’t sure so they had to call us back. What seemed like an hour later, they called and said they had one in a Baltimore warehouse but because it was the holiday, we couldn’t get it until Wednesday. Whelp. There went the entire weekend. We gave up the ghost and called Tow Boat US. They came within 45 minutes and not much more than that we were sitting on our dock. (THANK YOU TOW BOAT US).

Later that weekend I browsed dozens of websites and even took a stroll into Fawcett to see what some other options might exist to replace the muffler. The cannister style mufflers just wouldn’t work without a lot of refitting. We waited for Wednesday, and the 90 mm Vetus waterlock LP replacement muffler was picked up from Bacon. Other than being gray in color it was a perfect match. They saved my bacon, for sure.

I slapped it in within less than 30 minutes, and I started the engine. All was well, and we had water coming out the back of the boat.

Not so fast! The 23.5 cm long hose coming off the exhaust elbow and feeding the muffler was bulging like it was demonized.

I made that split decision to investigate further, so I pulled out the elbow and looked down the center of the hose with a nice bright flashlight. I wasn’t surprised to find that the hose had some real problems on the inside.

That hose seemed like too big of a risk, so I picked up a new hose from West Marine. BTW: Good luck finding a hose this large in diameter on a Saturday afternoon. With the new hose in hand, my victory was soon to be achieved. I loosened the exhaust elbow clamp so that the elbow could move, and effectively took the elbow off the turbo momentarily. Then I pushed the elbow onto the hose and tightened the clamps. All I had to do was to get the exhaust elbow (with it’s hose and muffler attached) to clamp onto the turbo.

The elbow wasn’t sealing like I wanted it to. I struggled to manipulate the heavy assembly and get the elbow face to seal perfectly. After several frustrating attempts where the two faces remained on an odd but small angle difference apart, I considered the concept to tighten the clamp and that this would cause the elbow face that the turbo face to seal. SNAP! The t-bolt on the clamp failed. That was a big whoops.

After I cleaned the exhaust elbow and inspected it, I immediately started searching on the internet for the right clamp. (I could not believe this nightmare was still continuing.) Out of desperation, I ordered clamps from auto parts stores and from two different marine shops online. These clamps have very different profiles, but it is very hard to tell this from online pictures and part number matches.

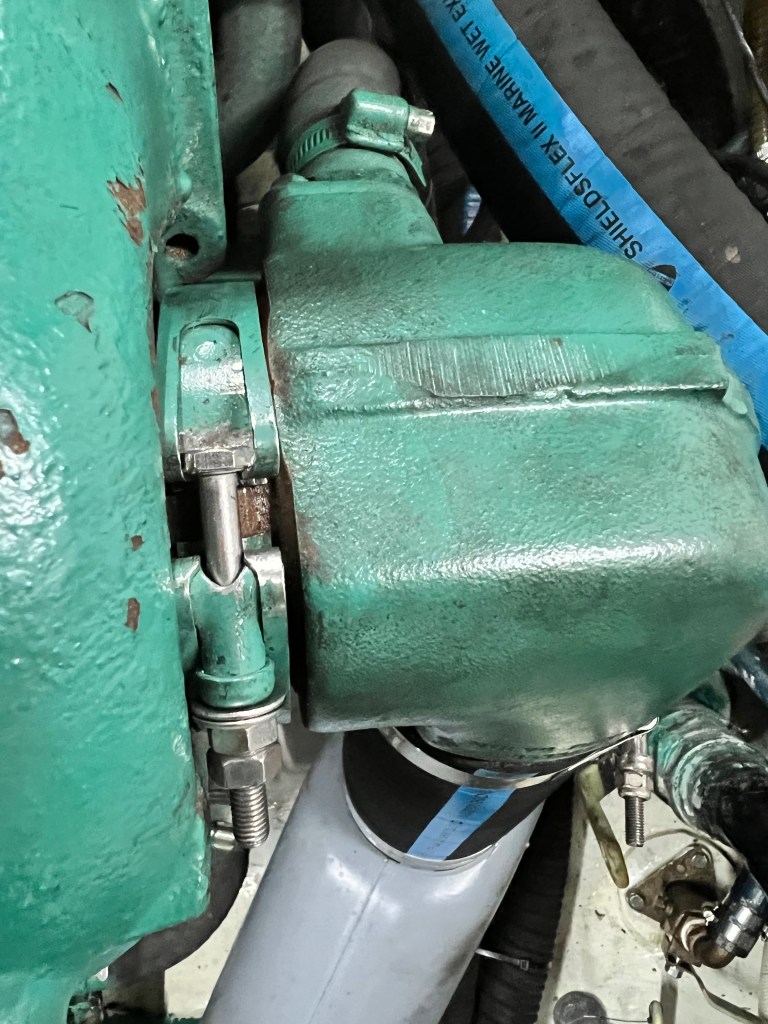

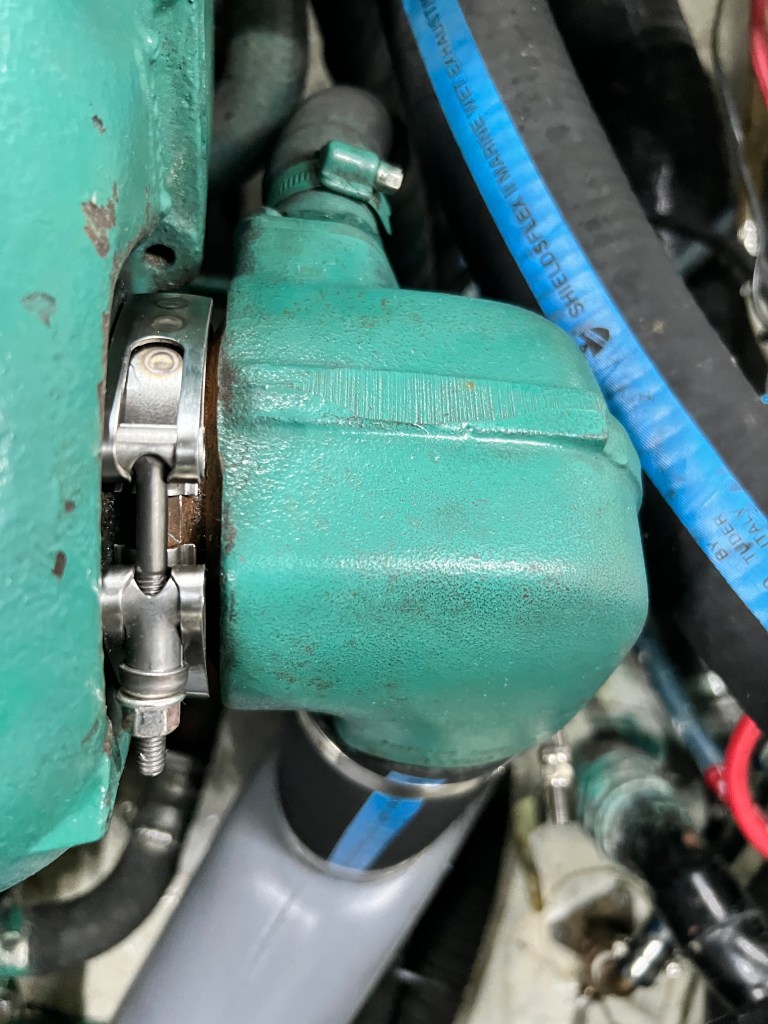

Waiting for the right one to arrive would wipe out another weekend. I impatiently wanted to get out on the water and test the engine which had obviously overheated. I had a new hose and muuffler installed, and the only thing stopping me was a clamp. I decided to improvise: I used a right-sized hex bolt to secure the elbow clamp just enough to make a run out into the Bay. It held just fine. But the question is…would you have done this?

Look closely: You can see from these pictures that not all clamps are created equal. The profiles of these V-band clamps are all very different and their widths and general design are not the same. The quick and easy solution from AutoZone resulted in a mess in the engine bay which I had to clean up. It was so wide and had the wrong profile that it didn’t seal the exit of the turbo and sea water splashed all over during a quick test. I don’t know what I was thinking trying to use an auto part for our marine service.

Everything is fixed now, and the engine is running fine. We have a startup procedure and will not take shortcuts like this again. But the debate is still alive on Skyward — to close or leave open the thruhulls.

If I am left with no other option than to to ‘rig’ something to get us out of a jam, I will do it again.

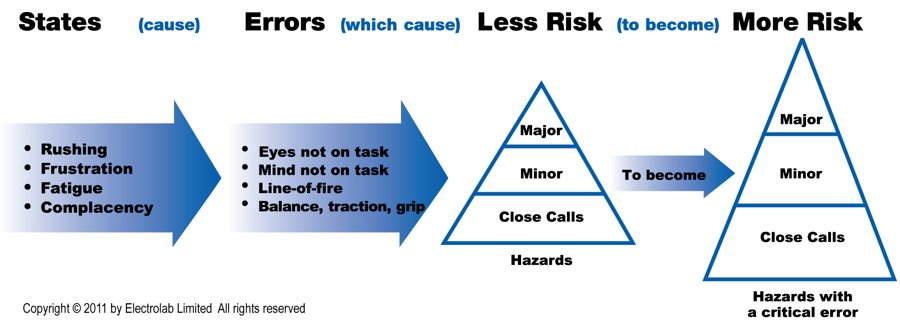

Of all people, I should know better to rush because rushing leads to mistakes. If you want to learn more about how rushing is one of the 4 top reasons for safety incidents, check out SafeStart.