A WindPilot Pacific Plus came installed on the transom, and I believe it was installed some time between 2002 and 2004. I have only used this autopilot a few times since 2021.

After a short day of Winter projects and while walking away from the boat, I turned around and glanced at the transom. Doesn’t everyone look back at their boat when walking away? I noticed that the auxilary rudder was not aligned with the main rudder; it was not aligned with the centerline of the boat.

This put me immediately in troubleshooting mode. I tried to rotate the auxilary rudder while standing on the ground it torsionally along its axis. I was able to rotate it at least 5-10 degrees. Even with this “slop”, I couldn’t get the auxilary rudder to be 100% aligned with the centerline of the boat.

As I mentioned, we haven’t used the WindPilot but a few times. It is almost useless on the Chesapeake Bay because the winds are variable and we don’t normally travel a long distance since we are still land based. One time two seasons ago, I recall that I lightly brushed up against a dock piling while reversing into the slip. Wiggling the auxilary rudder got me thinking about that one moment as the root cause so I started studying the WindPilot drawings.

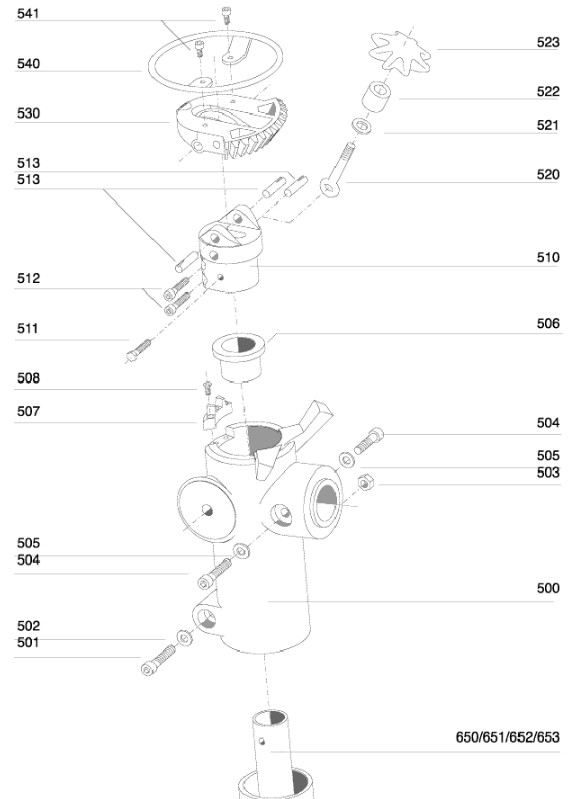

WindPilot has a lot of information on their website. Careful study of this exploded diagram shows that the shaft 650 was aligned and held in place by one M8x35 bolt, 511 through a hole in the upper end of 650. I suspected that this incident from 2022 may have stressed bolt 511 or elongated the hole in 650 where the bolt goes through. All I had to do was remove the system and diagnose.

I dropped the entire assembly off the boat by removing the rudder from the assembly with 6 bolts. Then I removed the pendulum rudder and wind vane assembly. Finally, I dropped the remaining assembly 500 from the transom.

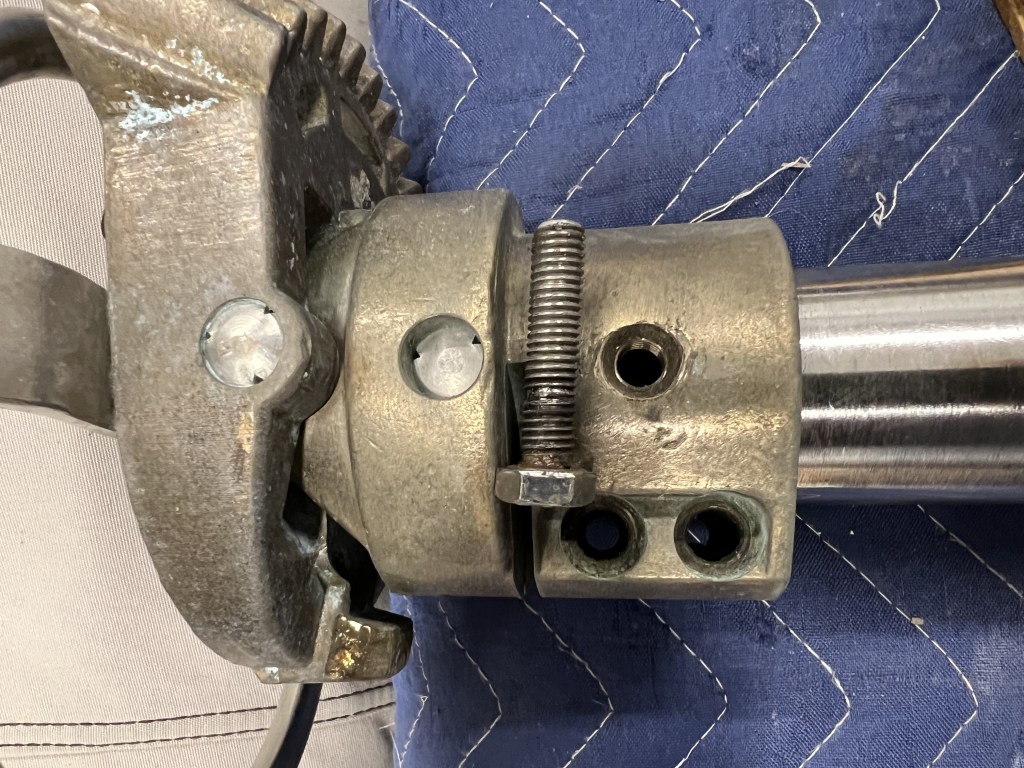

The mounting brackets will have to be removed another day. I loaded up the pieces carefully and put them in the garage for closer inspection. There was little time wasted in pulling apart the shaft from the clamp head, 510.

What I found was interesting. Bolt 511 had a couple of thread that were damaged. Once I separated the shaft from the clamp head, 510, I expected to see an elongated hole caused by a slightly forceful touch of a dock piling. Instead, what I noticed is that the hole in the shaft is oversized by several millimeters.

The hole was big enough to give a lot of slop along the axis which is exactly what I was experiencing. The hole was uniform in diameter. So there is the culprit. It is highly likely that the shaft was either fabricated with too large a hole or the shaft had been previously modified by an owner along the way and unknowingly the hole was made too large. There is no chance that my piling encounter caused this.

I could easily see that the design of the shaft with only one hole causes a weak point. The bolt 511 doesn’t really do anything after a few millimeters in this design; the length could be much shorter and it would not impact performance. In my opinion, the bolt 511 should go all the way through the shaft and across the clamp head 510.

What’s next? I am going to keep the WindPilot off for this sailing season. As mentioned, it doesn’t provide any added value sailing on the Chesapeake like we do now. I will see if Ray can work his magic on improving the design of the shaft/bold/clamp head assembly.

UPDATE: I discovered that bolts 512 were not tightened fully on the clamp head 510. Once properly tightened, the shaft will not have slop.