The original USB charging in the cockpit (at the charttables) had not worked in a while. It is located on the port side behind the chartplotter. While aboard the HR48 “Astra” on the last trip to Antigua, I found it very useful to have working USB charging in that location for phones and GPS units.

I started to pull apart the devices and wiring to get a better look at what was going on. The tabs on these original 24V chargers looked like they had rusted pretty good and they were flimsy like a loose tooth.

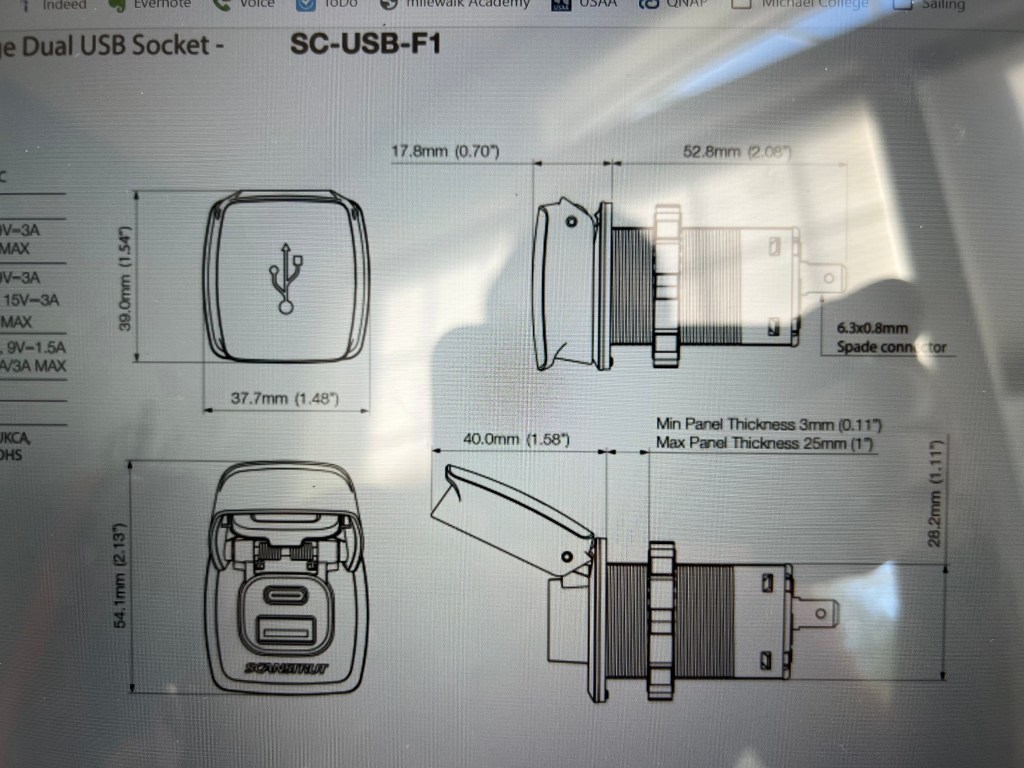

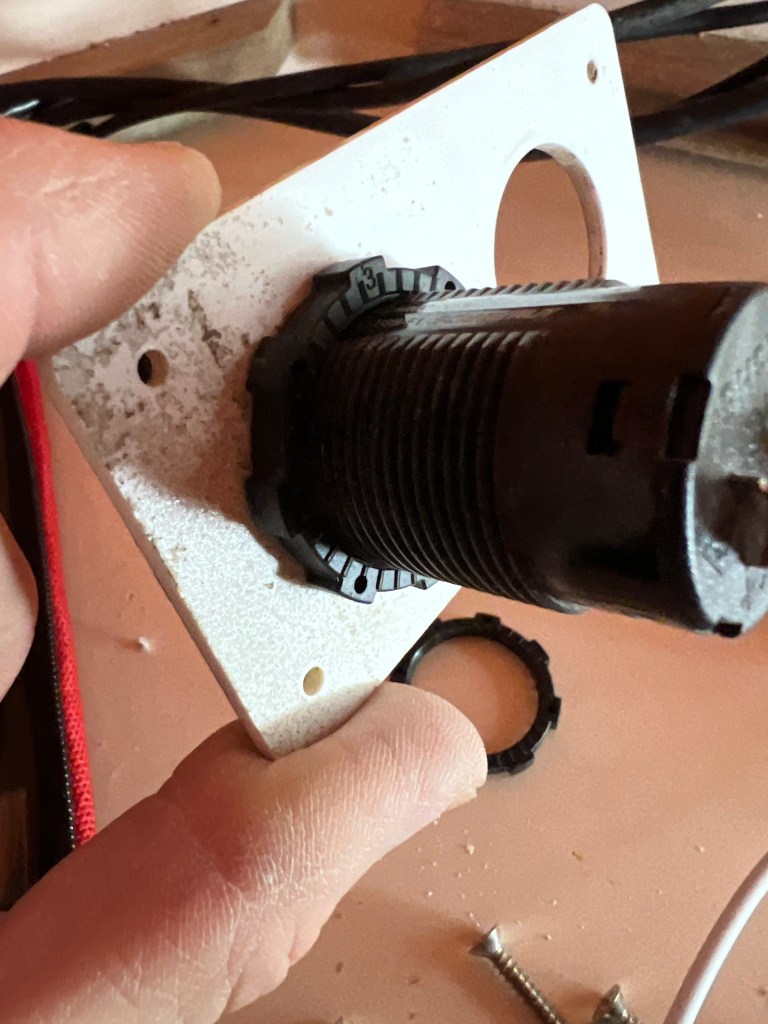

The original wiring connectors also looked to be corroded. I knew this could be a quick project and a big win. I found the perfect USB connectors on Defender from Scanstrut SC-USB-F1 for $34. Based on the technical drawings, I sketched up the new hold design on the original stainless steel backplate.

The beauty of the reusing the old backplate was that I knew the screw holes would work. Ray made me a black plastic backplate that I could install quick and easy. Well…it turns out that the new USB connectors are longer than the original 24V. When I went to test fit the new setup, it interfered with the fiberglass wire chase/tube that runs underneath the cockpit coaming. I found a 3/8″ or 1/2″ thick piece of teak or mahoganny and made a new backplate. I finished it off with several coats of varnish. Then I wired up the new chargers. It looks and works great.

We had a single rope clutch on the port side of the mast sitting on a winch pad. Our Dyneema genoa halyard ran through the clutch, but our topping lift could only be tightened with a winch. That meant that the topping lift would consume an entire winch, which made no sense. The pad flange was wide enough to hold a double 12mm Lewmar rope clutch. I tapped the mast with a 3/8″-24 tap and used 3/8″-24 bolts x 3/4″ long. Now both the topping lift and the genoa halyard have their own rope clutch and can be routed to the 44ST Lewmar winch just below the new rope clutch.

We removed the Windpilot Pacific Plus II from the transom, because we didn’t see a need for that autopilot system on Skyward. When removing the brackets, we discovered that the butyl tape was not sealing well and allowing water intrusion on the lower bracket. The transom got worn down to the fiberglass in some areas due to heavy use of polishers. We hired EH Boat Repair to repaint the transom. They built a fixed scaffold and enclosure to do this while we were on the hard at Bert Jabins Yacht Yard. I think it turned out well.

If you are interested, The Windpilot is for sale:

Hi Jeff,Not sure if you are too far along

LikeLike