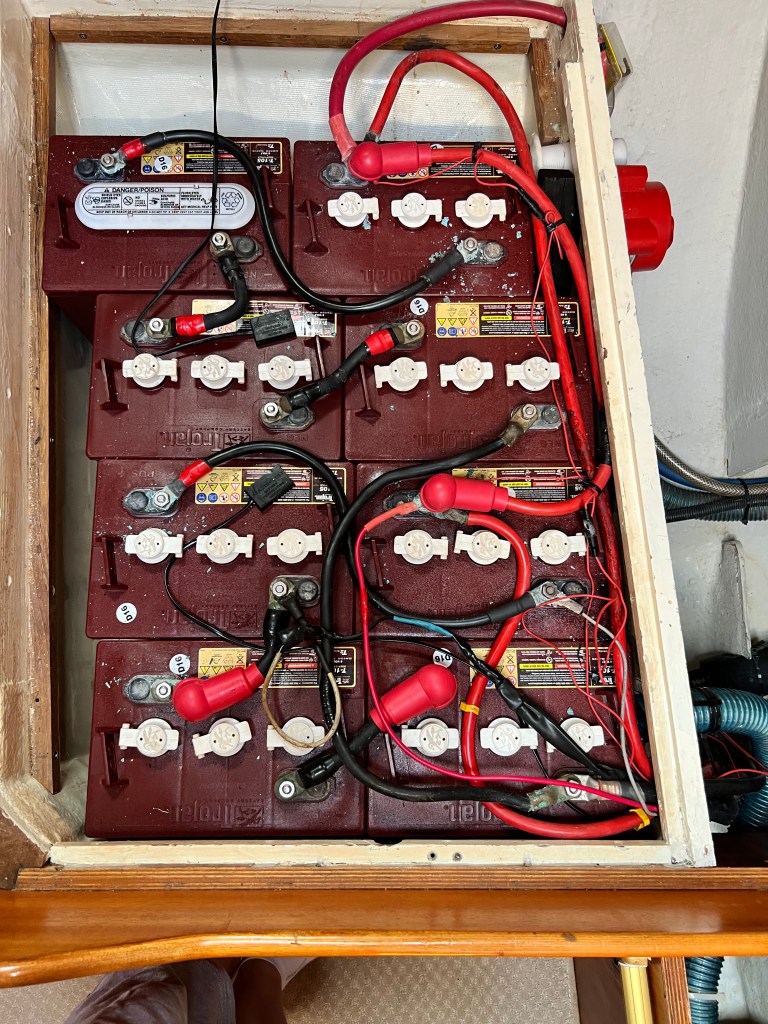

Replacing our 8x 6V Trojan golf cart led-acid batteries that make up our house bank has been on our list since our survey in May 2021. This is what it looked like under our aft starboard double bed.

If that picture makes you scratch your head, then hearing that these batteries percolate and vent gases constantly won’t be a surprise. We have adjusted our charge controllers, and this has not had much success in correcting the problem. These batteries were organized to have 4 batteries in series (24v) and have two banks tied in parellel giving around 450 Ah of service (20-hour rate).

We couldn’t pass up a great deal from Pasco Battery Warehouse at the Annapolis Spring Sailboat Show on 4x Lifeline AGM 12V 4DL batteries. Then the daunting challenge of figuring out how and where to organize these new batteries took us a few weeks to sort out given that we were consumed with deck, rigging, and so many other projects. They sat in the garage, and my son who is a 3rd year electrical engineering student suggested we go with a node approach to wire up these 4 batteries.

This theory was surprisingly identical to Nigel Calder’s recommendations from the class that Rachel took from him last year during the Fall Boat Show. We knew that 4 AGMs would not fit in the same space as the 8 T-105 Trojans, so we had to come up with a plan to put the 4th battery in another location. I decided to build a separate battery box and place it adjacent to the existing and original battery box on the starboard side.

I made the box out of 3/4″ Okoume marine plywood screwed together. I epoxied the corners and top edges, then I fiberglass tabbed the internal corners to rigidity. Then I finished the box with about 2 coats of Bilgekote. It fit nicely in the open space just aft of the original battery box. We used 2/0 wire between all batteries and external devices like fuse blocks, switches and terminal blocks.

Getting the old batteries (62 lbs) out and the new batteries (124 lbs) in was perhaps the easiest task of the entire project. I rigged up a 4:1 lifting block set with a snap shackle on each end and connected it to the end of the boom. This allowed us to raise or drop batteries through the aft hatch. I didn’t take pictures of this, but with me up top and Rachel in the aft cabin we did this work swiftly and safely.

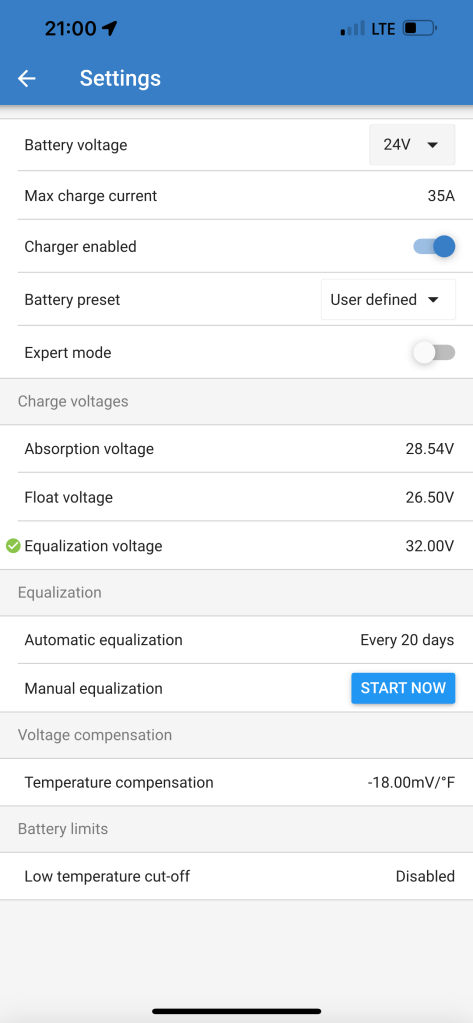

Finally, we configured our Victron solar charger, Balmar alternator external regulator and battery chargers for our new AGMs. We love using our Victron iPhone app to adjust our charge controller and visual indicators; here is a screenshot:

Every time we do these types of projects, we always run into a “what were they thinking” situation. We were shocked (no pun intended) to see that the previous owners had the high output alternator temperature sensor cable spliced up from phone/ethernet line to 16 AWG all with electrical tape and they secured it directly to a positive terminal of from of the T-105 Trojan batteries!

I’m sure that some future owner will look at our work and say the same thing about us. If we cannot perfect a system by re-doing it or replacing it, the we at least try to improve the system or anything that we touch. In this case, we enhanced the fusing for the whole boat to 500 Amps with a new fuse block and we installed a positive terminal block for our bow thruster, windlass and other items coming directly to the bank. We caught this design flaw when the 130 Amp fuse popped during some testing.

Apart from the battery project, we replaced the cockpit locker-to-engine compartment hatch. It is a Nuovo Rade 355mm x 600mm hatch. The nice thing about this project is that it dropped right in place. This was easily the most simple project I have ever done on this boat.