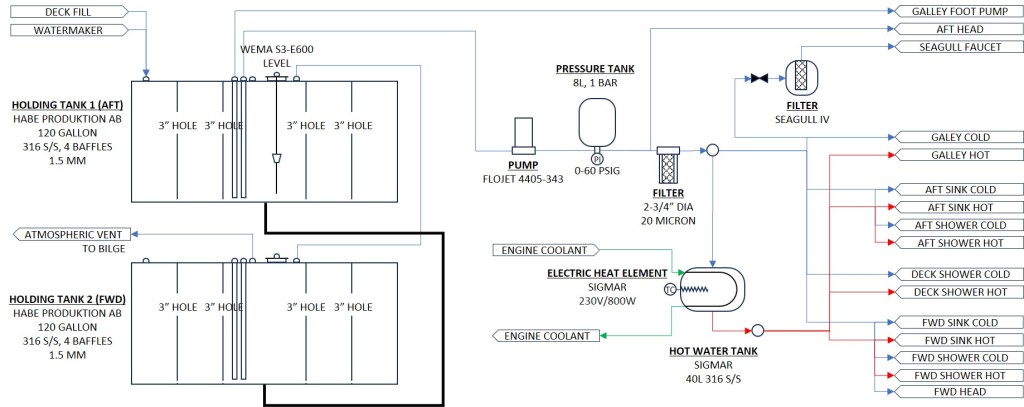

We couldn’t take the smell any longer. There was obviously something wrong with the water coming out of our water tanks, and it was time that I investigate the situation. Skyward has two (2) stainless steel tanks built in 1996 with 1.5 mm thickness. The tanks are installed laterally in the center of the boat below the floorboard in our salon area.

We are lucky. Skyward can store a total of 240 gallons, which is helpful for offshore and remote cruising, or doing a trip out to Block Island, or even being on anchor in the Chesapeake for a few days. Drawn out, our potable water system includes the two tanks, a main pump, a pressurized bladder tank, a polishing filter, a SeaGull filter, and a hot water system.

A couple of years ago, I replaced the pressure tank and re-worked several lines in the engine compartment. Earlier this year (2024) during the Winter season, I removed and cleaned out the hot water tank. What I saw then should have alerted me that we had bigger issues, but I was pre-occupied with other projects at the time. This Spring, every single faucet smelled terrible, and we were definitely not willing to wash our hands much less drink from the system.

Fortunately, we have years of experience in cleaning and preparing stainless steel systems. As chemical engineers, we are intimately familiar with best practices in the pharmaceuticals, chemicals and cosmetics industries in dealing with contamination. Here was the plan that I had organized:

- Visually inspect the tanks by opening up the inspection ports

- Drain all water from the existing tanks

- Wash down the tanks with high pressure water and some soap to remove as much contamination with impingement / scouring action

- Apply a treatment to break down the mold, mildew and other proteinaceous compounds

- Rinse down the treatment with fresh water

- Apply a treatment to address any surface rust and prepare the surface

- Rinse down the treatment with fresh water

- Replace all filters

- Replace the deck fill hose

- Refill the tanks with filtered fresh water and monitor

I read online that some people who smell (or taste) something odd with their water system will just dump a small amount of bleach into their tanks. To me, that is a passive approach which may be a short-term solution, but might not necessarily solve the problem. (NOTE: Bleach in a plastic system may be a good solution, but not always in a stainless steel system). Being a Lean Six Sigma Black Belt, I am an advocate of the Define Measure Analyze Improve and Control (DMAIC) approach. In this case, this means that I open up the tanks to go and see what the problem is.

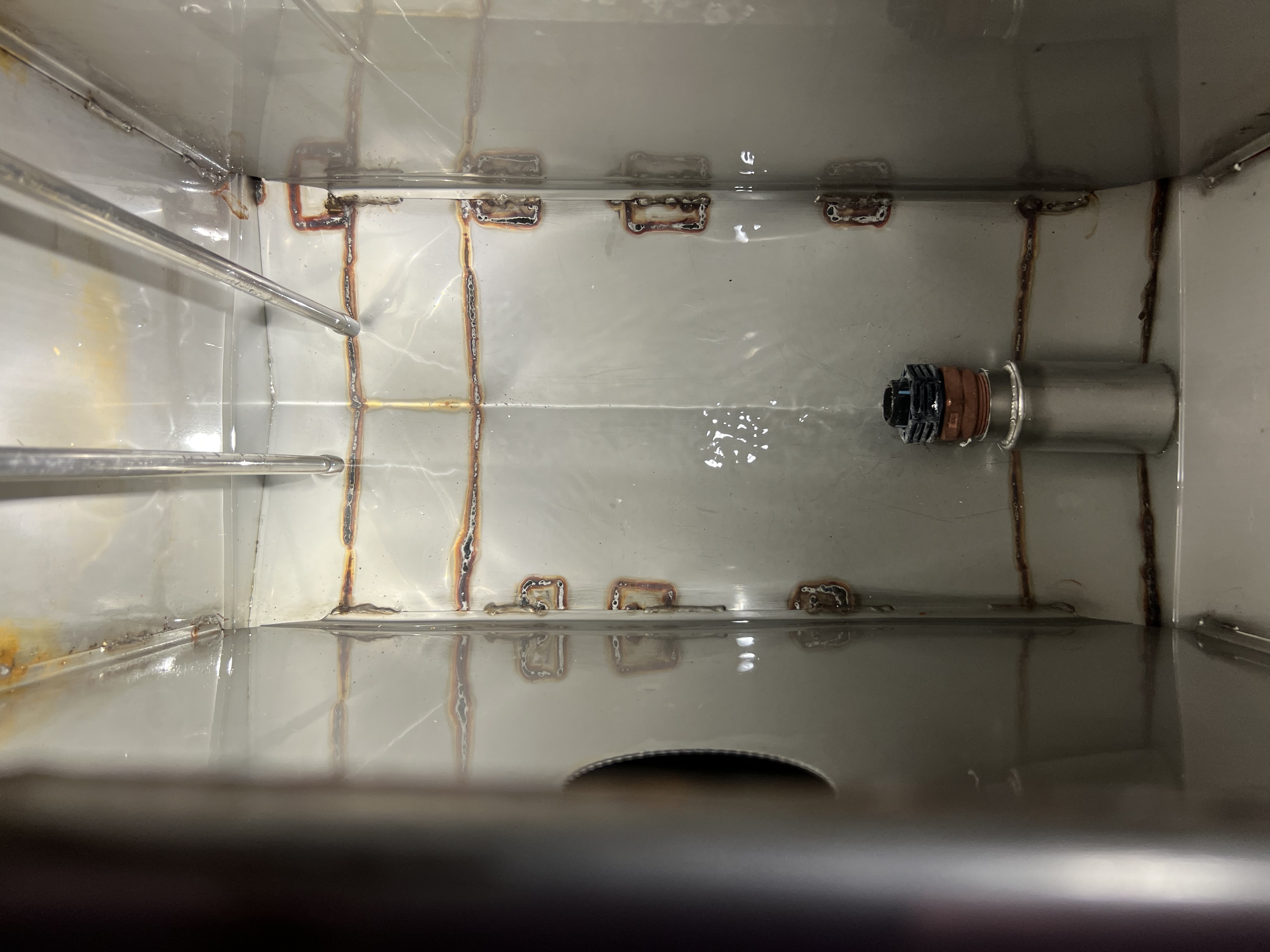

Upon visual inspection, it was clear that we had both a mold/mildew/organic problem and also a rust issue. We had significant growth on the sidewalls and in the baffled areas. We also had some biofilm visible on the walls. Furthermore, it appeared that welds were being attacked by corrosion, most likely to previous use of chlorinated water. Warning: These images are gross!

Once I sprayed the tanks down with fresh water, the remainder of the contamination was biofilm, some surface mold which I could not reach (baffled areas), and weld corrosion. I had my work cut out for me. But the next step is the first and most important: Get rid of all the mold.

I like to use an enzyme treatment, and luckily I still had about 1 lb of Tergazyme from Alconox. Tergazyme is a concentrated, anionic detergent with protease enzyme for manual and ultrasonic cleaning. It is a white powder that can be purchased…funny enough…from tattoo shops.

I mixed that with about 15-20 gallons of hot water and poured it into the tanks. 20 gallons in a 240 gallon system is not a lot. I didn’t have a full recirculation system, so I would have preferred to fill the tanks with the solution to the brim, but that would have cost me $240 in materials alone. We opted to use what we had, then we went sailing to slosh the material around as much as possible. We vacuumed all material up, because this cannot be dumped into the sea.

Rachel did all of the flushing, because I couldn’t get my arms into the 3″ diameter holes in each of the baffles. She cut up her arm pretty good, but she was determined, and it worked brilliantly. This was backbreaking and painstaking work.

We followed this up with something called passivation. Passivation is a method to prepare the surface of stainless steel and to increase the resistivity to corrosion. We used a solution of citric acid and hot water. Hot water is key; the hotter the better. As before, this material can NOT be dumped into the sea as it is at pH 1, and you have to wear proper PPE when handling this chemical to avoid physical harm. We neutralized this solution with sodium bicarbonate (baking soda) and measured the pH before discarding. You have to understand the chemical reaction to get the right mixture for neutralization.

After multiple rounds of flushing with fresh water, the final results are impressive. The mold is completely eliminated and the rust has been scavenged off the surface of the welds quite well. The tanks are restored enough for us to be comfortable using the water for everyday activities like washing dishes, showering, etc. We will include a full tank re-inspection each year in our maintenance program.

A small amount of the treatment chemicals and all of the fresh water flushes have gone through our distribution system. As such, the polishing filter (20 micron) was overloaded. This had to be be changed out before we could start using the system. All faucet screens were removed, scrubbed and flushed before re-installing.

Finally, the last job was to replace the deck fill line(s) which had obvious contamination. These lines were at least 20 years old.

Once the system was restored and filled with clean water, I could tell that the polishing filter was working well.

Our system is 27 years old, and I feel that it is now almost as good as new. This took us about 3-4 days of labor -some very long days- which included the sailing to slosh around the liquid in the tanks. If I had more time and money, I would engineer and use a chemical recirculation skid much like we have used in our jobs. This would include spray wands, pumps, recirculation systems, etc. These systems are about $50,000 used and are fully automated, but I think we could build one much cheaper.

If you are having smelly odors from your water system, take the time to open up your inspection ports and take a look at what is going on in your tanks. You might not like what you see, but you will be glad you did it.